How to Increase Manufacturing Efficiency with Vibratory Bowl Feeders

Increase Manufacturing Efficiency with Vibratory Bowl Feeders & Automated Parts Feeding

Vibratory bowl feeders, and all automated parts feeders for that matter, can play a significant role in increasing manufacturing efficiency. In today’s fast-paced manufacturing environment, efficiency isn’t just a goal—it’s a necessity. For manufacturers looking to streamline their operations and boost productivity, vibratory bowl feeders and automated parts feeding systems can offer transformative benefits.

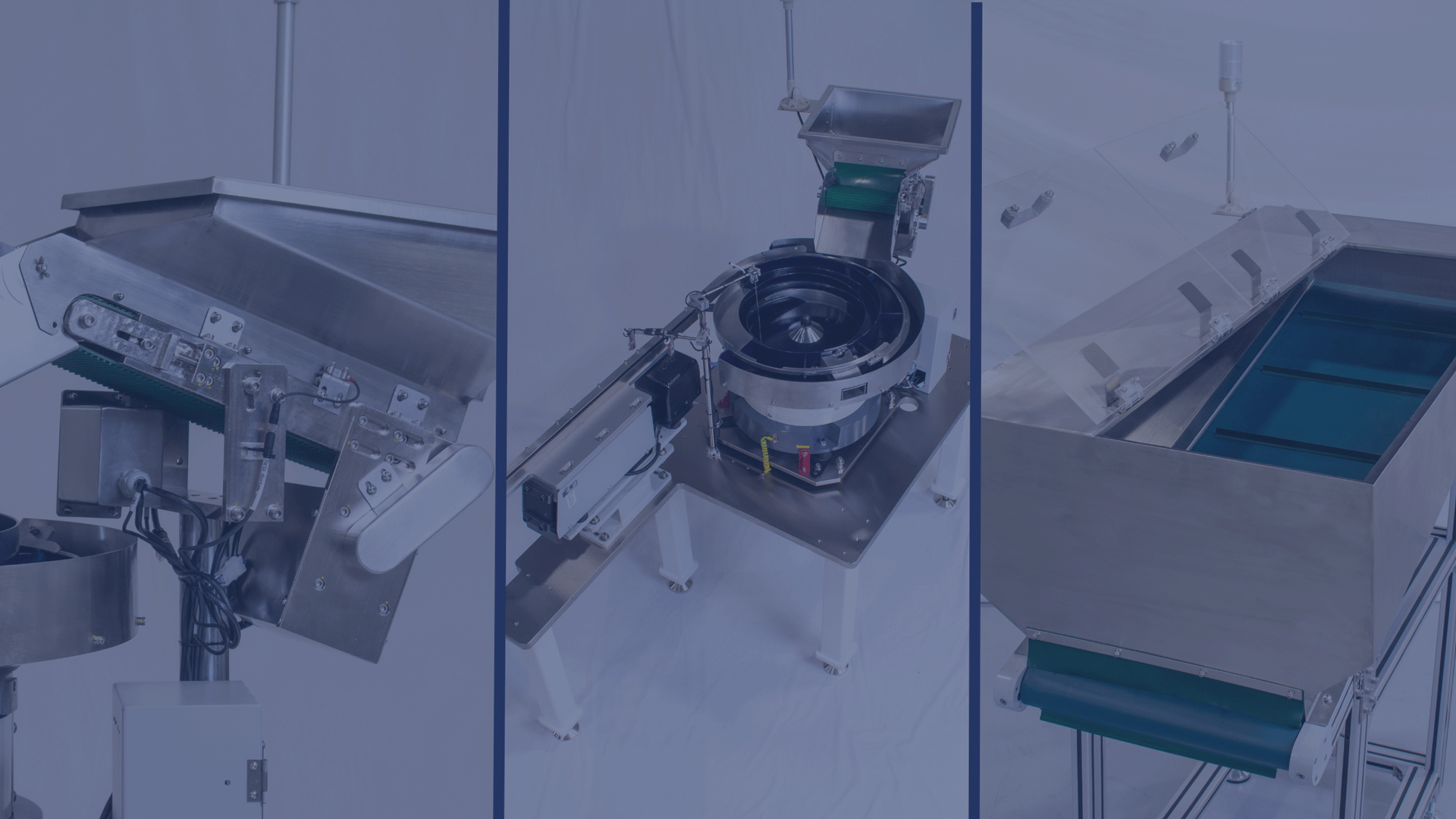

What Are Vibratory Bowl Feeders?

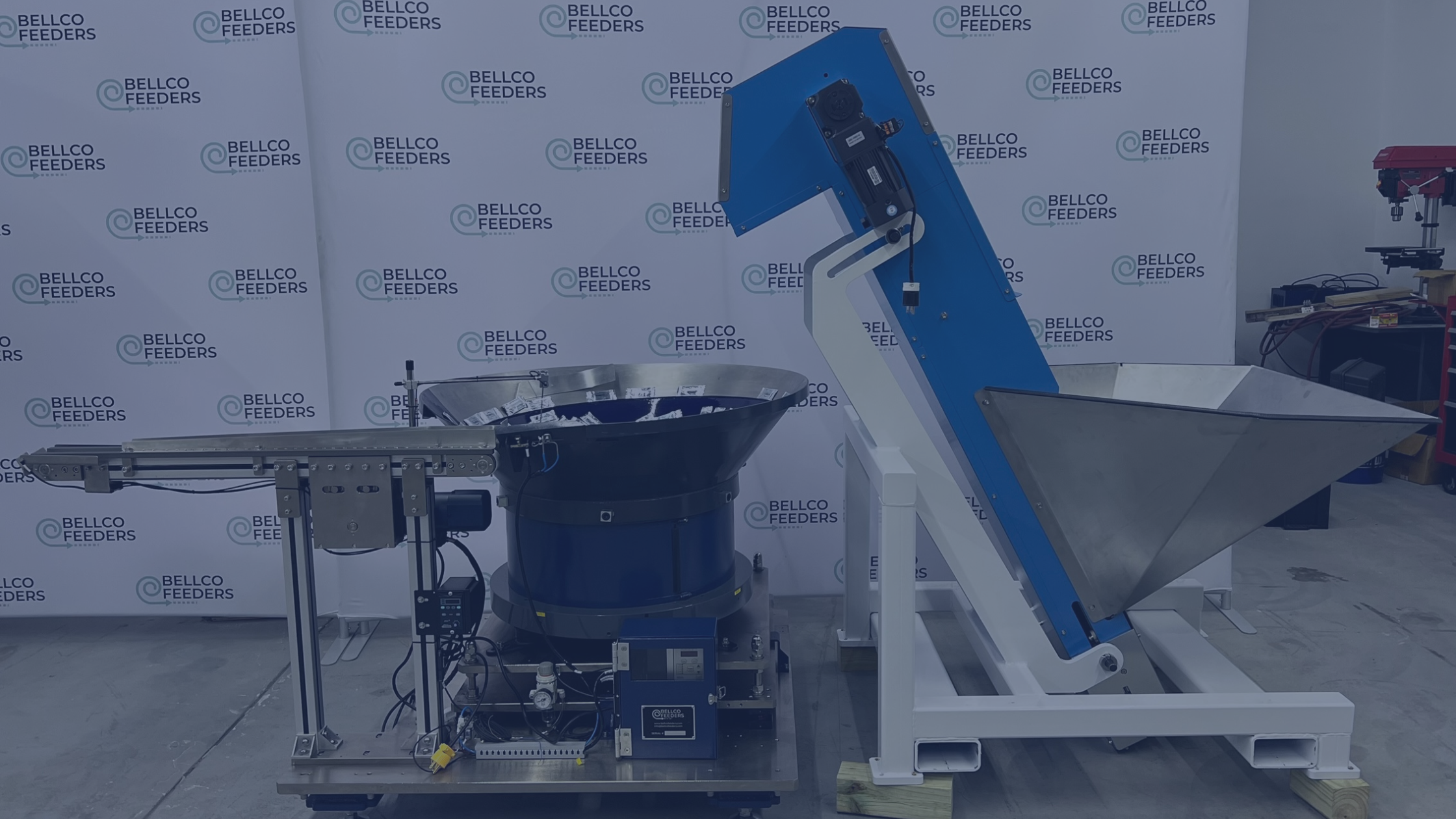

Vibratory bowl feeders are automated systems designed to handle and orient parts for assembly or further processing. Using vibration to move and sort components, these feeders ensure that parts are presented consistently and accurately, reducing manual handling and improving overall efficiency. Further enhanced by hopper feeders, these systems can be designed to run automatically for long periods of time without operator interaction.

Key Benefits of Vibratory Bowl Feeders

-

Enhanced Speed and Throughput: Vibratory bowl feeders can handle high volumes of parts quickly and reliably. Their continuous and consistent operation supports faster production rates, helping you keep up with demanding schedules and increasing your overall throughput.

-

Improved Accuracy: Precision is critical in manufacturing. Vibratory bowl feeders ensure that each part is correctly oriented and positioned, minimizing errors and enhancing the quality of your final products.

-

Reduced Labor Costs: By automating the feeding process, vibratory bowl feeders reduce the need for manual intervention. This not only lowers labor costs but also minimizes the risk of repetitive strain injuries among workers.

-

Versatility and Flexibility: Whether you’re working with small, intricate components or larger parts, vibratory bowl feeders can be customized to handle a wide range of items. This adaptability makes them suitable for various industries, from automotive to consumer products.

The Role of Automated Parts Feeding Systems

Beyond vibratory bowl feeders, automated parts feeding systems include solutions like linear vibratory feeders, bulk part hoppers or pre-feeders, elevated parts conveyors, rotary feeders, and custom automation setups. These feeder applications further enhance manufacturing efficiency by:

-

Reducing Downtime: Automated systems operate continuously, reducing downtime associated with manual feeding and part handling. This leads to smoother production flows and less interruption.

-

Increasing Accuracy and Consistency: Automated systems ensure that parts are consistently fed and oriented, which is crucial for maintaining high standards of quality and reducing defects.

-

Optimizing Workflow: Integrating automated feeding systems into your production line helps streamline operations, improve part handling, and ensure that each component is processed efficiently.

Why Invest in Automated Feeding Solutions?

Investing in vibratory bowl feeders and automated parts feeding systems is a strategic move for manufacturers aiming to improve efficiency, reduce costs, and maintain high-quality standards. These systems not only enhance operational speed and accuracy but also offer long-term benefits by optimizing workflow and minimizing manual labor.

At Bellco Feeders, we specialize in designing and manufacturing custom vibratory bowl feeders and automated feeding solutions tailored to meet your specific needs. Discover how our high-quality, cost-effective systems can transform your manufacturing processes and drive your success.

Ready to take your manufacturing efficiency to the next level? Contact us today to learn more about our innovative feeding solutions and how they can benefit your operations.