Bulk PartHoppers

Custom Part Hoppers from Bellco Feeders: Essential for Efficient and Unattended Operation

Enhancing Feeder Performance and Reducing Operator Involvement

A bulk parts hopper is a crucial component in the automated feeding process, designed to minimize manual intervention and ensure the smooth operation of your feeder system. By efficiently managing the supply of parts, hoppers play a key role in enhancing feeder performance and maintaining consistent production flow.

Key Functions of a Bulk Parts Hopper

Minimizing Operator Interaction: The primary function of a bulk parts hopper is to reduce the need for constant operator involvement. By automatically replenishing the feeder bowl with parts, the hopper allows for extended periods of unattended operation, freeing up valuable operator time for other tasks.

Maintaining Consistent Feed: The hopper regulates the number of parts in the feeder bowl by adding more as needed. This continuous supply helps to minimize downtime caused by part shortages and ensures a steady and reliable feed rate. As a result, production processes become more efficient and less prone to interruptions.

Designing the Optimal Hopper

When designing a hopper, we focus on two critical factors to tailor the solution to your specific needs:

1. Desired Unattended Operation Time: Understanding how long you want your feeder to run without operator intervention is crucial. This information helps us determine the appropriate hopper capacity to ensure that the feeder bowl remains consistently stocked with parts for the required duration.

2. Size and Weight of Parts: The dimensions and weight of the parts being fed are essential considerations in hopper design. These factors influence the hopper’s capacity, discharge mechanism, and overall configuration. Accurate details about your parts allow us to design a hopper that accommodates their specific characteristics and ensures efficient handling.

Our Expertise in Hopper Design

At Bellco Feeders, our team of experts specializes in designing bulk parts hoppers that meet the highest standards of performance and reliability. Here’s how we ensure you get the best solution:

- Customized Recommendations: Based on your requirements for unattended operation time and part specifications, we provide tailored recommendations for the type and size of hopper that will best suit your application.

- Optimal Design Solutions: We consider all relevant factors, including part flow characteristics, hopper material, and integration with your feeder system, to deliver a hopper that enhances overall efficiency and reduces maintenance needs.

Types of Hoppers

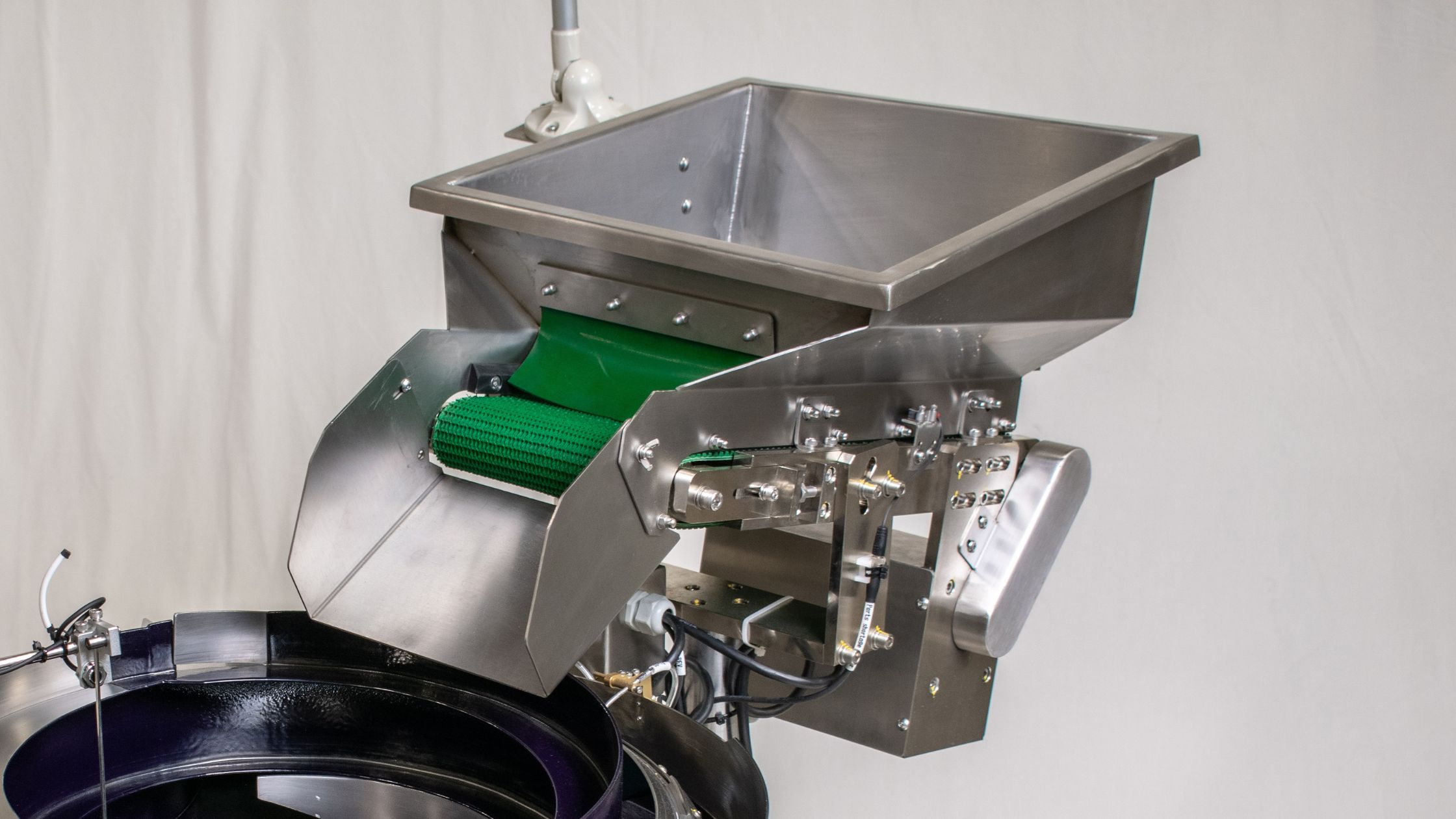

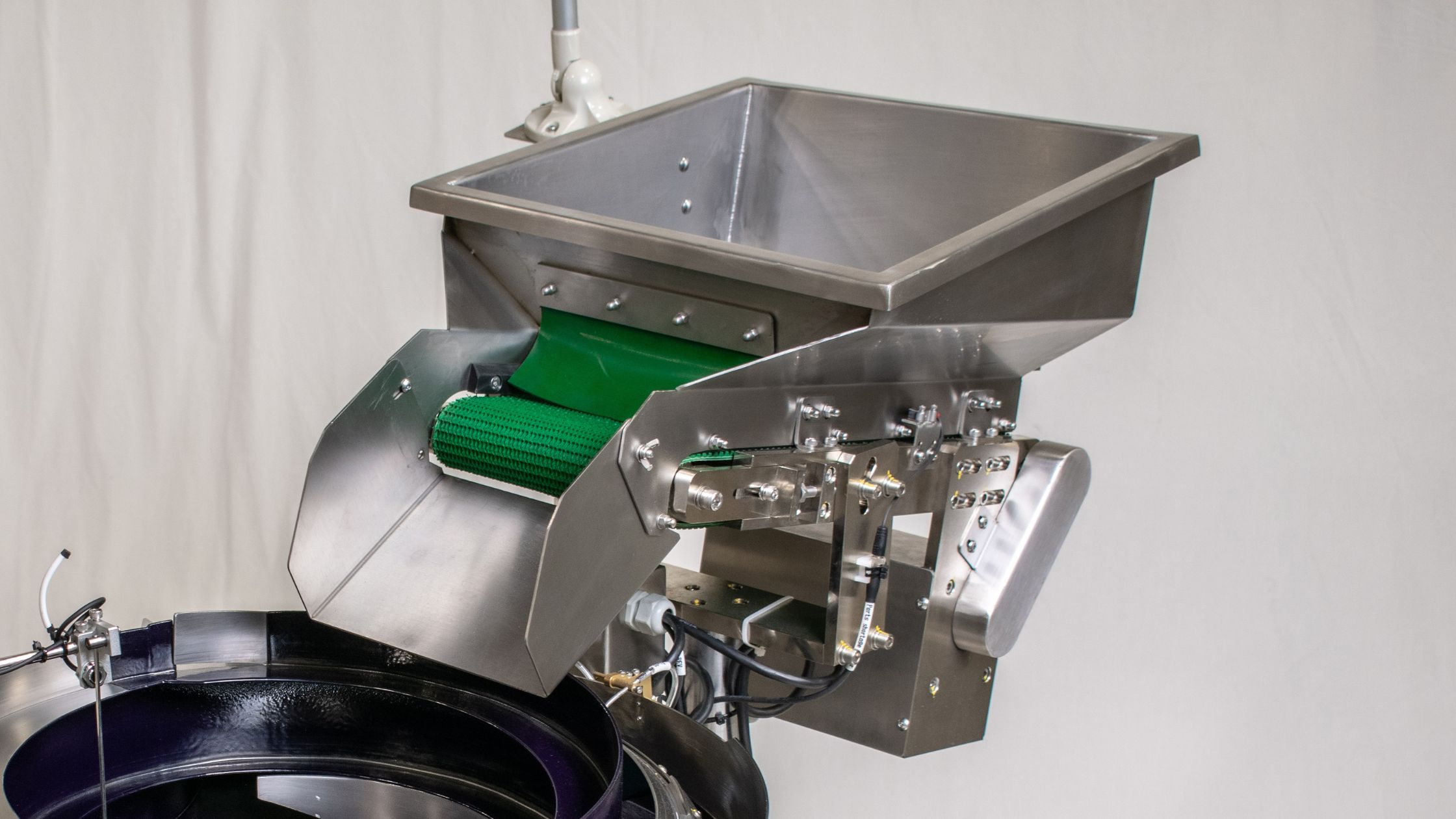

Stainless Steel Construction

All our hoppers are construction using 316 Stainless Steel for maximum durability, regardless of the manufacturing environment.

Our technicians take their time to ensure each weld line is straight and each surface is brushed consistently.

Why Choose Bellco Feeders?

Our commitment to excellence extends to every aspect of our feeder systems, including the design and implementation of bulk parts hoppers. With our extensive experience and attention to detail, we deliver solutions that optimize your manufacturing process and improve operational efficiency.

Contact Us Today

To learn more about how a bulk parts hopper can enhance your feeding system and reduce operator interaction, contact Bellco Feeders today. Our team will work with you to design and implement the perfect hopper solution for your specific needs, ensuring smooth and efficient operation.

Frequently Asked Questions

Because all of our hoppers are custom designed, our team of engineers will work with you to design the correct size for your application.

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.