VibratoryBowl Feeders

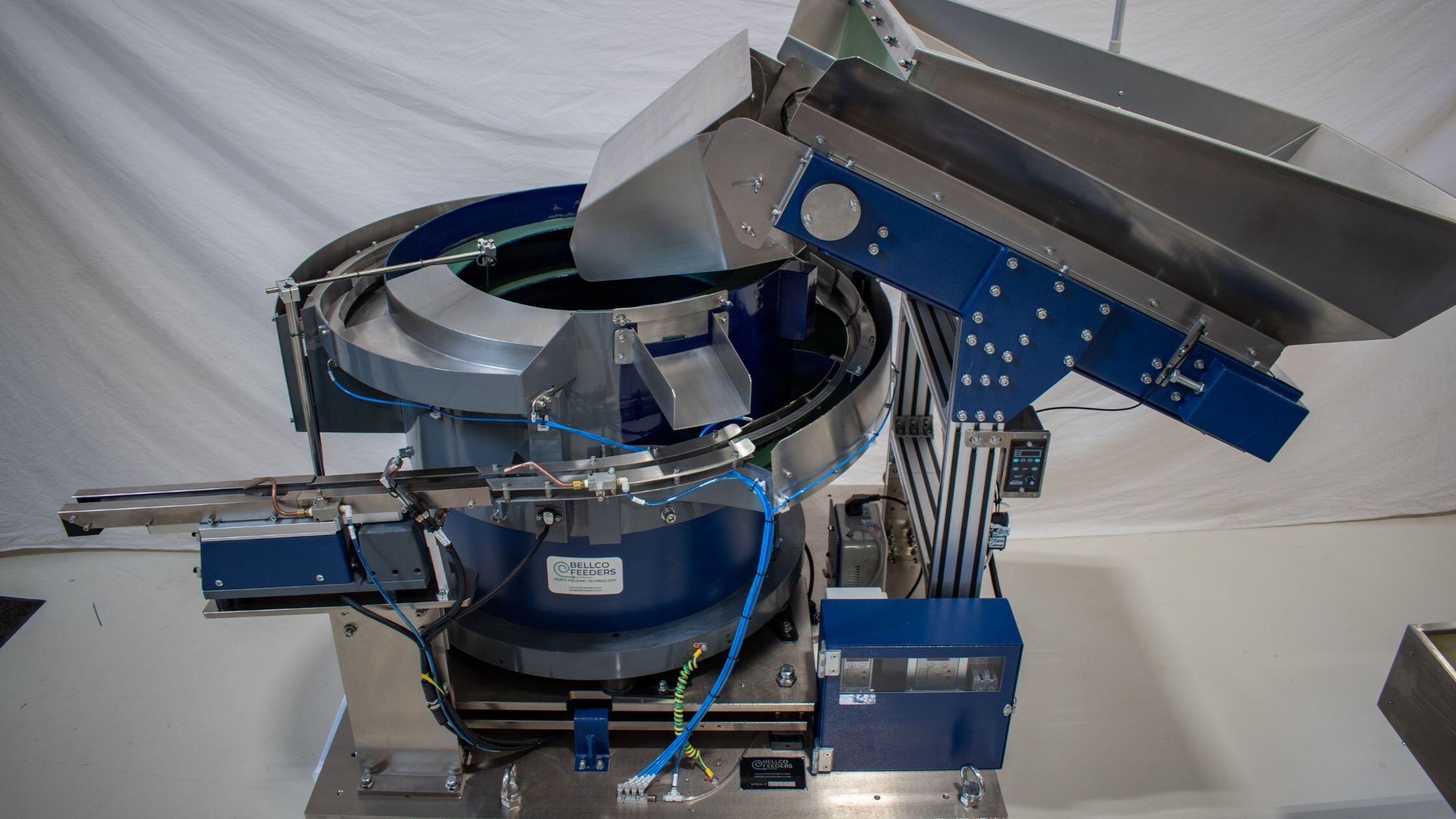

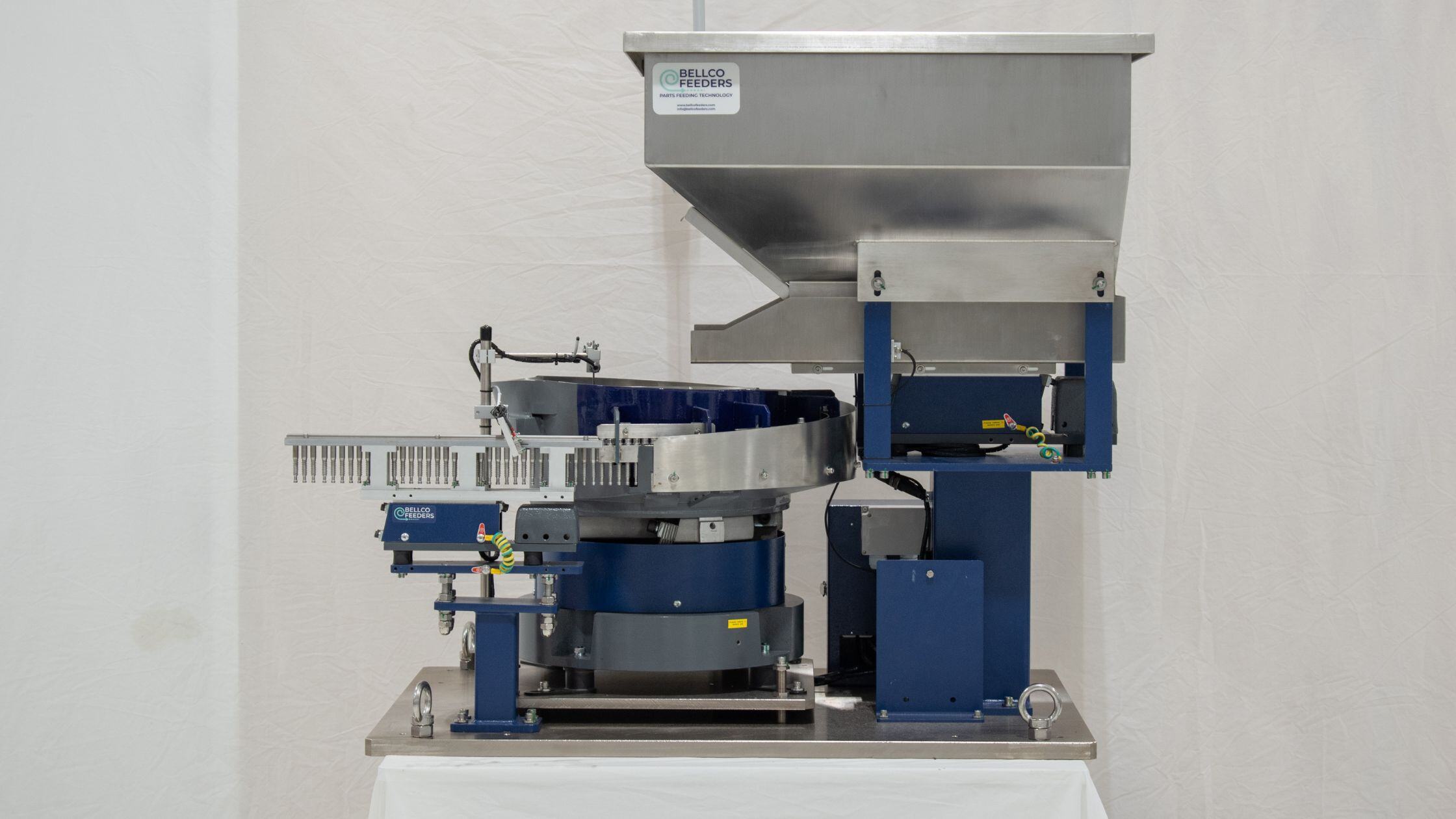

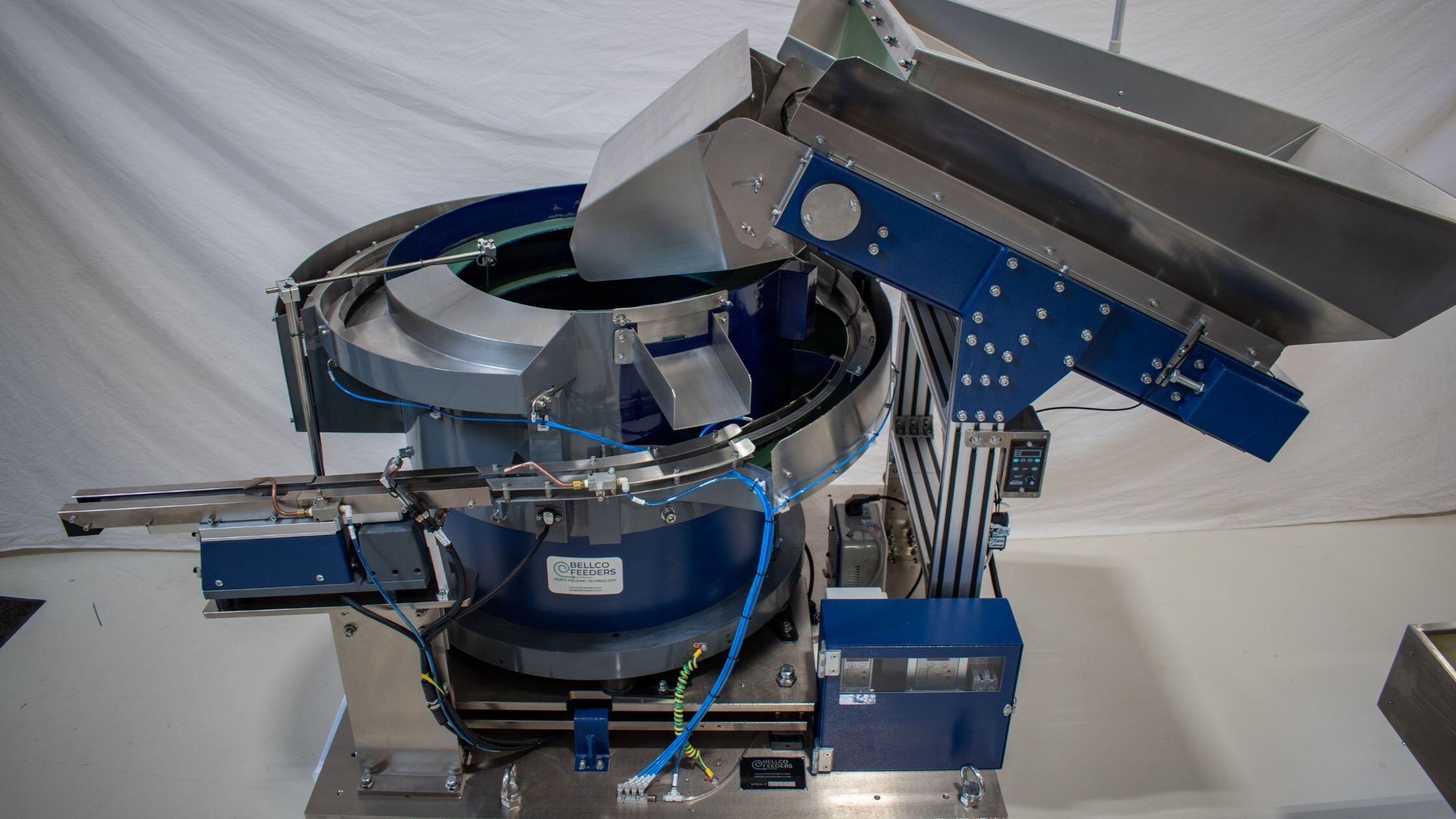

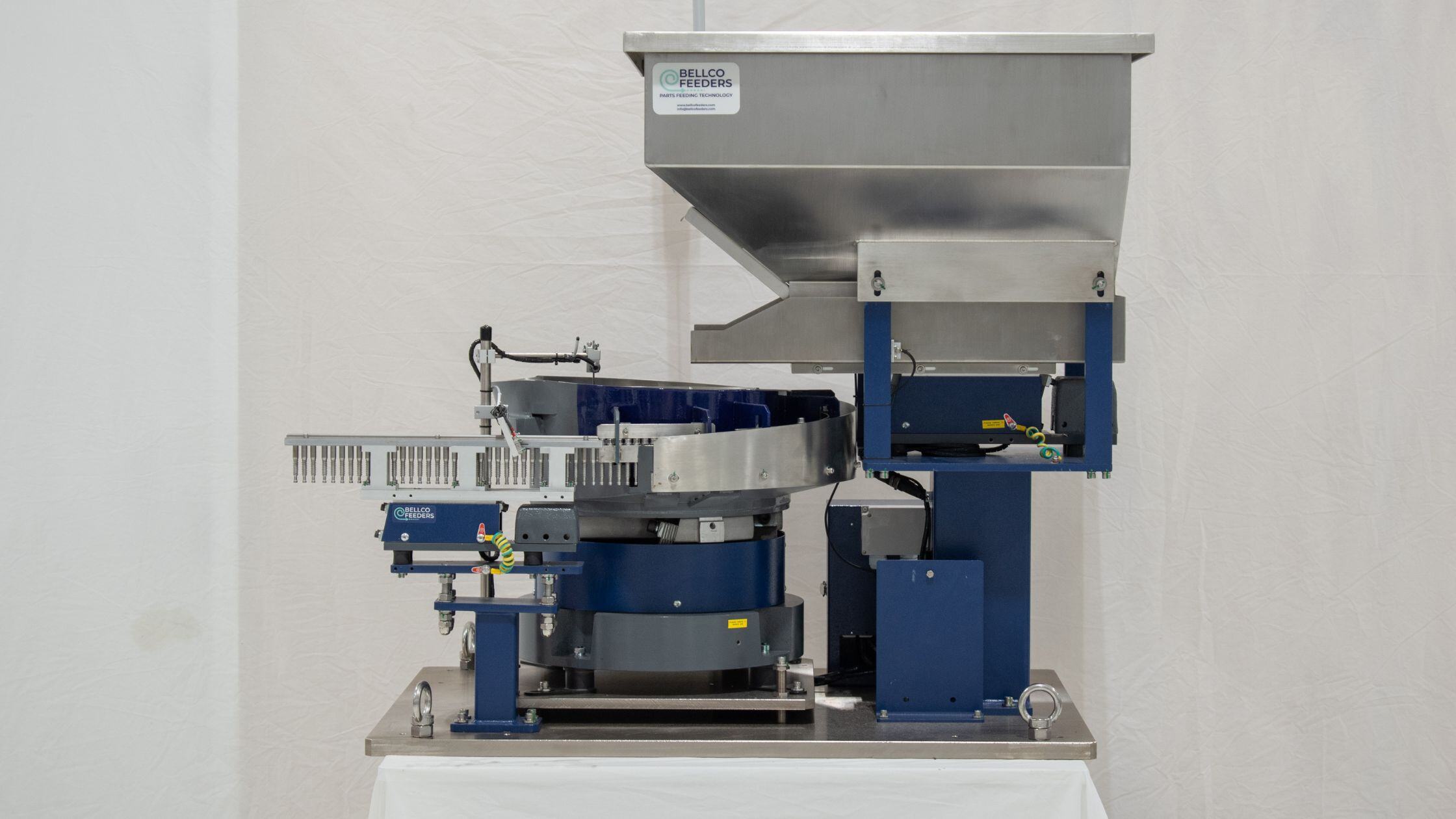

Custom Vibratory Bowl Feeders from Bellco Feeders

The Standard for Sorting, Feeding, and Orienting Parts

Vibratory feeder bowls are the backbone of automated manufacturing processes, offering a reliable and efficient method for sorting, feeding, and orienting components. These systems are essential in high-speed production environments where precision and consistency are key.

How Vibratory Bowl Feeders Work

Bulk Part Introduction: Parts are initially loaded into the vibratory feeder bowl from bulk containers. The bowl’s design allows for continuous and seamless feeding of these parts into the system.

Vibration Tuning: The bowl is equipped with a specialized vibration mechanism that is finely tuned to control the movement of parts. This vibration causes the parts to travel along a carefully engineered path, interacting with various tooling components.

Sorting and Orienting: As the parts move around the bowl, they pass through different tooling stations designed to sort and orient them. This process ensures that each part is positioned correctly before exiting the feeder. The result is a continuous flow of accurately oriented parts, ready for the next stage of production.

Exit and Integration: Once sorted and oriented, the parts are directed to the exit point of the bowl. From here, they are fed into the production line or assembly process, precisely aligned according to the required specifications.

Our Standard Package Includes:

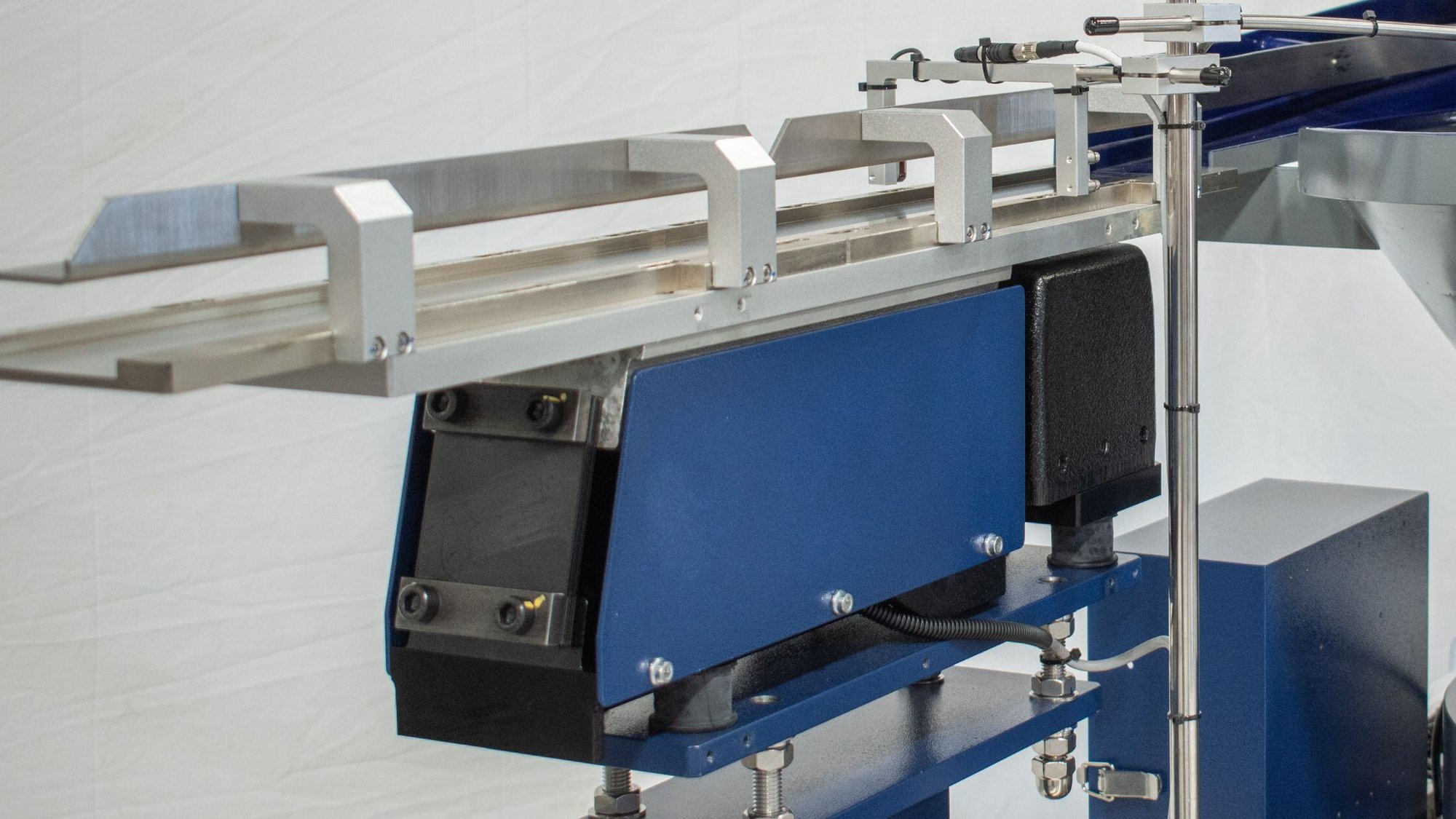

Linear Feeders

Our linear feeders are the most common accessory incorporated into our bowl feeder package.

This feeder works similarly to the bowl but, its main purpose is to move parts in a line to exit the feeder bowl system. This type of feeder can move the parts using vibrations and/or air guidance to any desired location away from the bowl.

A linear feeder also creates an accumulating buffer which makes sure a part is always ready to be unloaded and aids in feeder rate and output.

Feeder Accessories

Why Choose Bellco Feeders?

At Bellco Feeders, we are dedicated to providing top-of-the-line vibratory bowl feeding systems that deliver exceptional performance at highly competitive prices. Our systems are designed to handle a diverse range of part geometries and manufacturing needs, ensuring that you get a solution tailored to your specific requirements.

-

Expert Design and Engineering: With years of experience in designing and implementing vibratory bowl feeders, our team has the expertise to create custom solutions that meet the highest standards of quality and efficiency.

-

Custom Solutions for Every Need: We understand that every manufacturing process is unique. That’s why we offer customizable feeding systems to accommodate various part shapes, sizes, and production demands.

-

Cost-Effective Excellence: Our commitment to delivering high-quality systems at ultra-competitive prices means you get the best value for your investment without compromising on performance.

At Bellco Feeders, we pride ourselves on our ability to provide innovative and reliable feeding solutions that enhance your manufacturing operations. Contact us today to learn how our vibratory bowl feeders can optimize your production processes and drive efficiency.

Frequently Asked Questions

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.