Case Study: Vibratory Feeding Solution for Soft Plastic Snap Lids

| Industry: Packaging | |

| Rate: 70ppm/35ppm escapement | |

|

|

Components:

|

Project Overview

A prominent packaging company required a high-speed, reliable feeding solution for plastic snap lids. The challenge was to maintain a feed rate of 70 parts per minute (PPM) while preventing bending of the soft plastic. Additionally, the system needed to integrate seamlessly into the customer's existing automation line and ensure the caps were closed properly for the next stage.

Bellco responded with a tailored solution featuring:

- A vibratory hopper with a capacity of 10,000 caps to reduce manual refilling and increase efficiency.

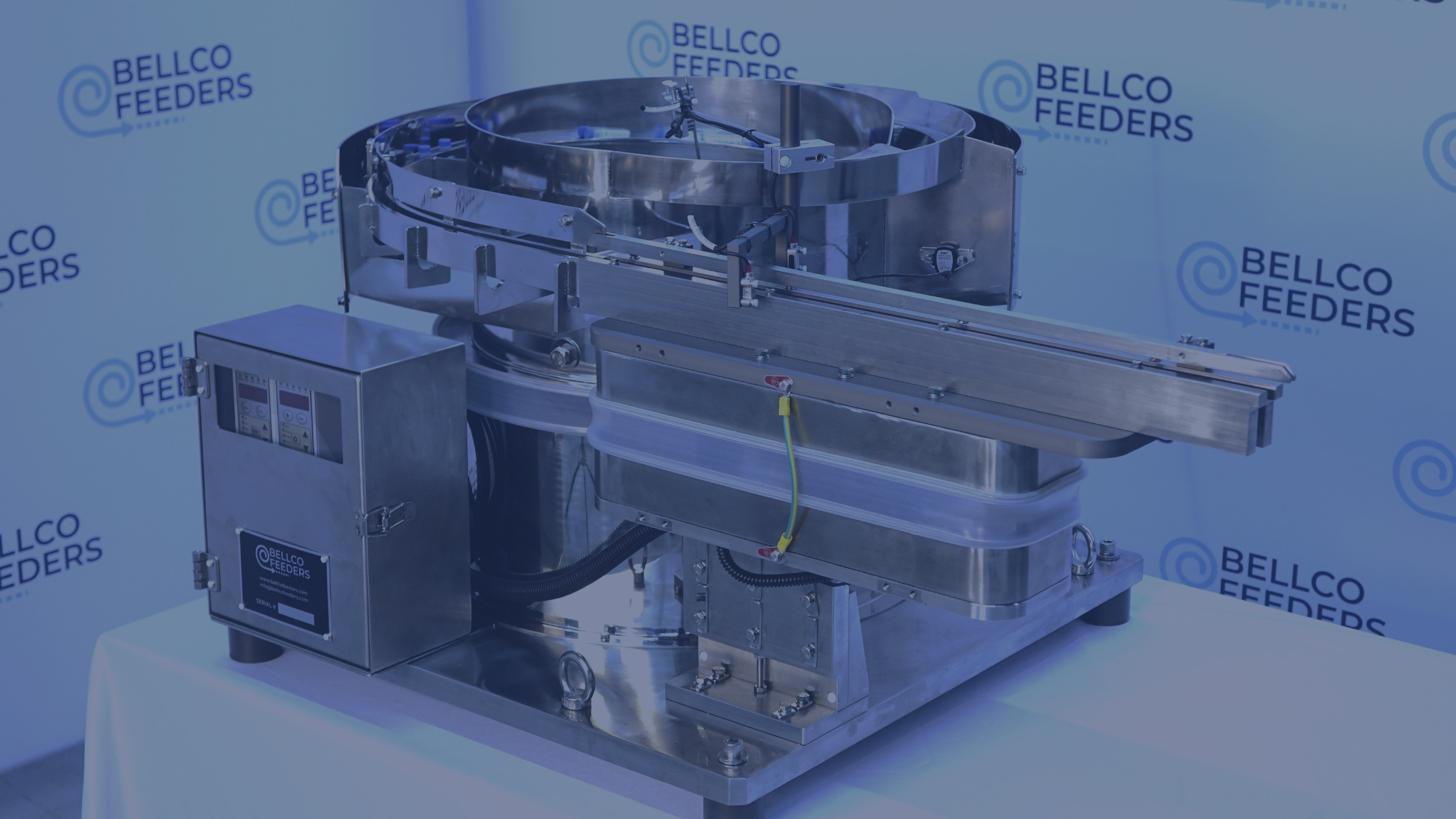

- A vibratory bowl feeder with a dual-lane linear track for optimized part flow.

- A two-lane pick-and-place escapement to ensure seamless part transfer.

With a 14-week lead time, including design, fabrication, and testing, Bellco successfully delivered a custom feeding solution tailored to the client's specific requirements.

Engineering the Solution

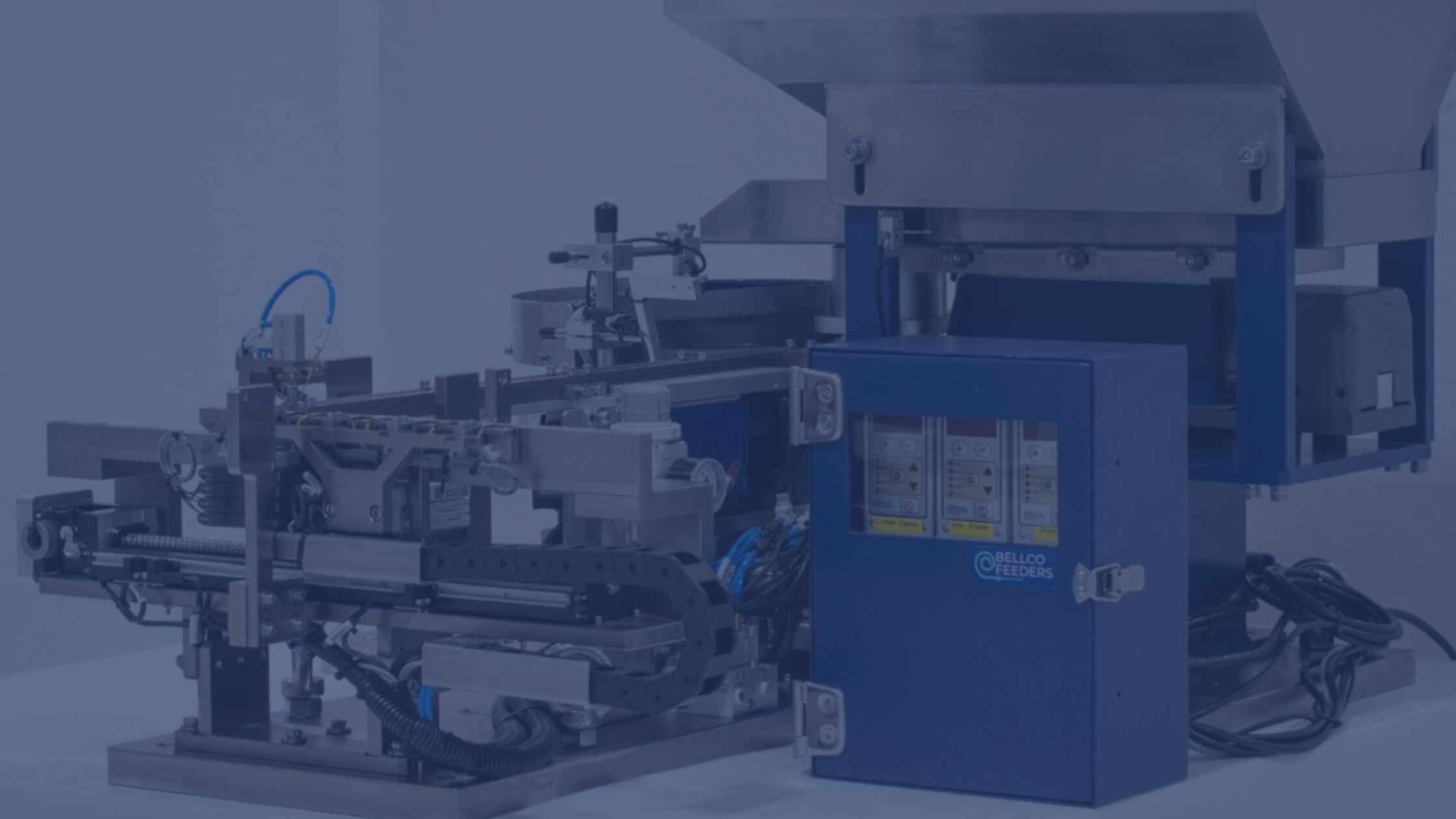

Bellco’s team of highly skilled design engineers utilized SolidWorks 3D CAD software to develop a fully customized feeding system. This approach allowed the client to review and approve the design in digital form before production began, ensuring full alignment with their needs.

Key Design Features:

-

High-Capacity Vibratory Hopper: Designed to hold 10,000 caps, minimizing the need for frequent manual refilling and keeping production running efficiently.

-

45 Degree Angle Dual-Lane Linear Track: Enhances efficiency; guides snap lids smoothly towards the escapement.

-

Precision Two-Lane Pick-and-Place Escapement: Feeds caps from two tracks into a rotary dial, ensuring proper closure before moving to the next stage.

-

Air Blow-Off System: Moves closed snap lids to the next stage of automation, ensuring smooth workflow.

SolidWorks CAD Model of Custom Escapement: Precision-engineered for smooth snap lid handling and integration.

Dual-Lane Track: High-quality craftsmanship for optimized part flow.

Custom design to keeps lids from falling and jamming on the rotary dial.

Rotary to pick-and-place escapement.

Overcoming Challenges

Problem: The soft plastic snap lids were difficult to feed because they were open and made of flexible plastic, making them prone to bending, misalignment, and jamming.

Solution: Bellco designed a custom feeding system with features to gently orient and hold the caps in place, ensuring they remained stable throughout the process. By integrating a rotary escapement to present the caps and a pick-and-place mechanism to position them correctly for closing, we were able to improve part handling precision and overall system performance.

To guarantee seamless integration, the client supplied Bellco with their PLC, PLC code, and control cabinet for rigorous in-house testing before installation.

Conclusion & Results

Bellco successfully delivered a custom-engineered vibratory feeding system that exceeded the client’s expectations. By addressing key design challenges and implementing innovative solutions, Bellco provided:

✅ Increased efficiency – Achieved a steady feed rate of 70 ppm, ensuring high-speed production.

✅ Seamless integration – Fully tested and validated with the client’s PLC system before installation.

✅ Reduced downtime – Custom design to keep the cap lids from falling and jamming on the rotary dial.

✅ Optimized workflow – The 10,000-cap hopper minimized operator intervention, leading to smoother production.

✅ Custom Paint Finish – Applied per the customer’s request.

This project highlights Bellco’s expertise in designing high-performance feeding solutions. With a commitment to precision engineering and innovation, Bellco continues to help manufacturers optimize their automation processes for maximum productivity.

Looking for a custom feeding solution? Contact Bellco today to discuss your automation needs!

FAQ

How does Bellco ensure seamless integration with existing automation systems?

Bellco provides SolidWorks 3D models for approval, conducts in-house testing with customer-supplied systems, and offers video run-off testing before shipment, ensuring a plug-and-play experience.

How long does it typically take to design and manufacture a custom feeding system?

Lead time is typically 10-12 weeks from the time of order to the time the system is in your facility.

How do vibratory bowl feeders improve automation efficiency?

Vibratory bowl feeders provide a consistent, reliable method for sorting, orienting, and feeding components in high-speed production environments, ensuring accuracy and efficiency.