SoundEnclosures

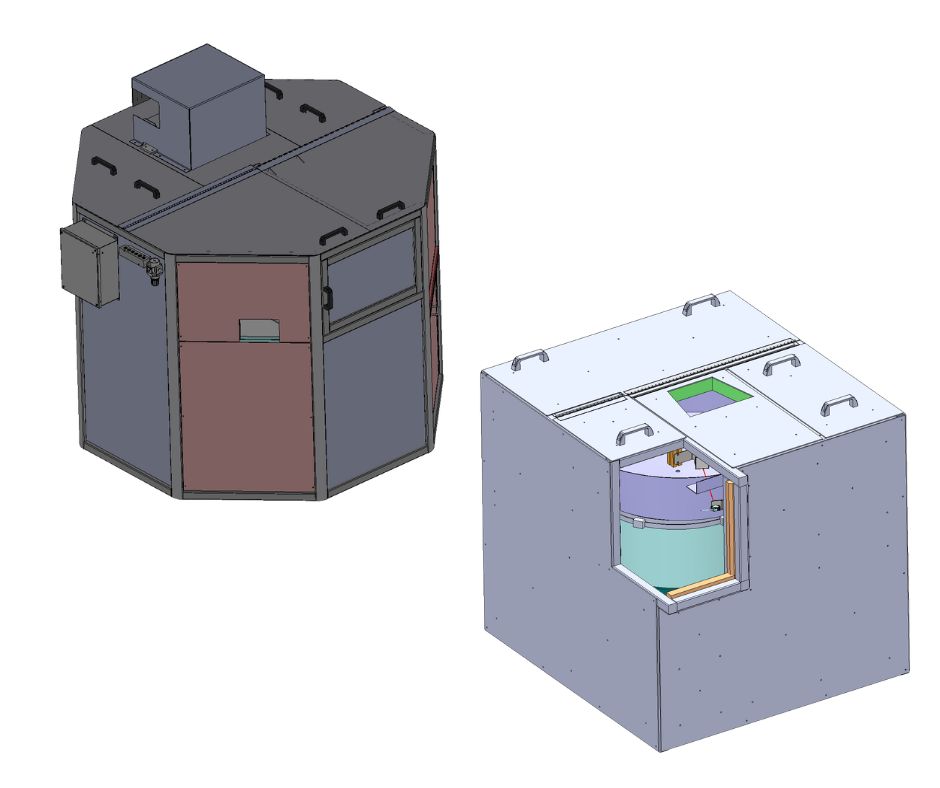

Custom Sound Enclosures from Bellco Feeders

Tailored Solutions for a Quieter Work Environment

At Bellco Feeders, we understand that managing noise levels is a critical aspect of maintaining a comfortable and efficient work environment. That’s why we offer custom sound enclosures designed to effectively reduce operational noise from our feeding systems.

Premium Design and Construction

Our sound enclosures are crafted with precision and attention to detail to meet your specific noise reduction needs:

- Aluminum Panels: The enclosures are constructed from high-quality aluminum panels, chosen for their durability and lightweight properties. This material not only ensures a robust and long-lasting enclosure but also contributes to its overall effectiveness in noise reduction.

- Acoustic Noise Deadening Foam: Inside the enclosures, we use advanced acoustic foam designed to absorb and dampen sound. This foam helps to significantly reduce the noise generated by the feeder systems, creating a quieter working environment.

Proven Noise Reduction

Our custom sound enclosures have been proven to reduce noise levels by an average of 30%. This substantial reduction helps to minimize distractions and enhance focus, contributing to a more productive and pleasant workspace.

Customized for Your Needs

We recognize that different manufacturing processes involve various types of parts and materials, each producing different noise levels:

- Part-Specific Solutions: The noise produced by parts moving within the feeder bowl can vary significantly depending on their material and shape. Our enclosures are designed with these variables in mind to ensure optimal noise reduction for your specific application.

- Manufacturer-Specific Requirements: Different manufacturers have distinct noise level requirements based on their operational needs and regulations. Our custom enclosures can be tailored to meet these diverse sound control needs, ensuring compliance and satisfaction.

The Benefits of Reducing Sound

Custom Engineered

Every manufacturing environment is a little different and each has it's own requirements. Likewise, each Bellco feeding system is unique. Different applications have different levels of sound output; many factors contribute to the amount of noise a system creates, including the part:

- Material

- Size

- Geometry

- Weight

Our engineering team will work with you to make sure the sound enclosures for your application meets your requirements.

Why Choose Bellco Feeders?

At Bellco Feeders, we are committed to delivering solutions that not only improve operational efficiency but also enhance your work environment. Our custom sound enclosures are part of our broader commitment to quality and customer satisfaction.

- Expert Design and Engineering: Our team of engineers has extensive experience in designing and manufacturing custom enclosures that meet the highest standards of performance and noise reduction.

- Tailored Solutions: We work closely with you to understand your specific requirements and create enclosures that perfectly fit your feeder systems and operational needs.

Contact Us Today

If you’re looking to reduce noise levels and improve your workspace environment, contact Bellco Feeders today. Learn more about our custom sound enclosures and how they can be integrated with your feeding systems to provide a quieter and more efficient manufacturing process.

Frequently Asked Questions

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.