What Are Vibratory Bowl Feeders and How Do They Revolutionize Manufacturing?

In today's fast-paced manufacturing environment, efficiency, precision, and automation are essential for staying competitive and keeping your manufacturing costs down. Vibratory bowl feeders were developed in the late 1940s and early 1950s and they revolutionized the way manufacturers handle parts. But what exactly are vibratory bowl feeders, and how have they transformed the industry?

What Is a Vibratory Bowl Feeder?

The initial concept for using vibration to sort and orient parts came from the need to automate the feeding process in industries like manufacturing and assembly.

The first vibratory bowl feeders were designed by engineers and inventors who sought a way to improve efficiency in parts handling. Early versions of these feeders used simple mechanical systems and vibration-driven bowls to move parts along a specific path for orientation and sorting. Over time, the technology advanced with improvements in control systems, materials, and design flexibility, which allowed for more precise feeding and handling of a wider range of parts.

Today, vibratory bowl feeders have evolved into highly customizable and sophisticated automation tools used in various industries, from automotive manufacturing to pharmaceuticals, helping to streamline production lines and reduce labor costs.

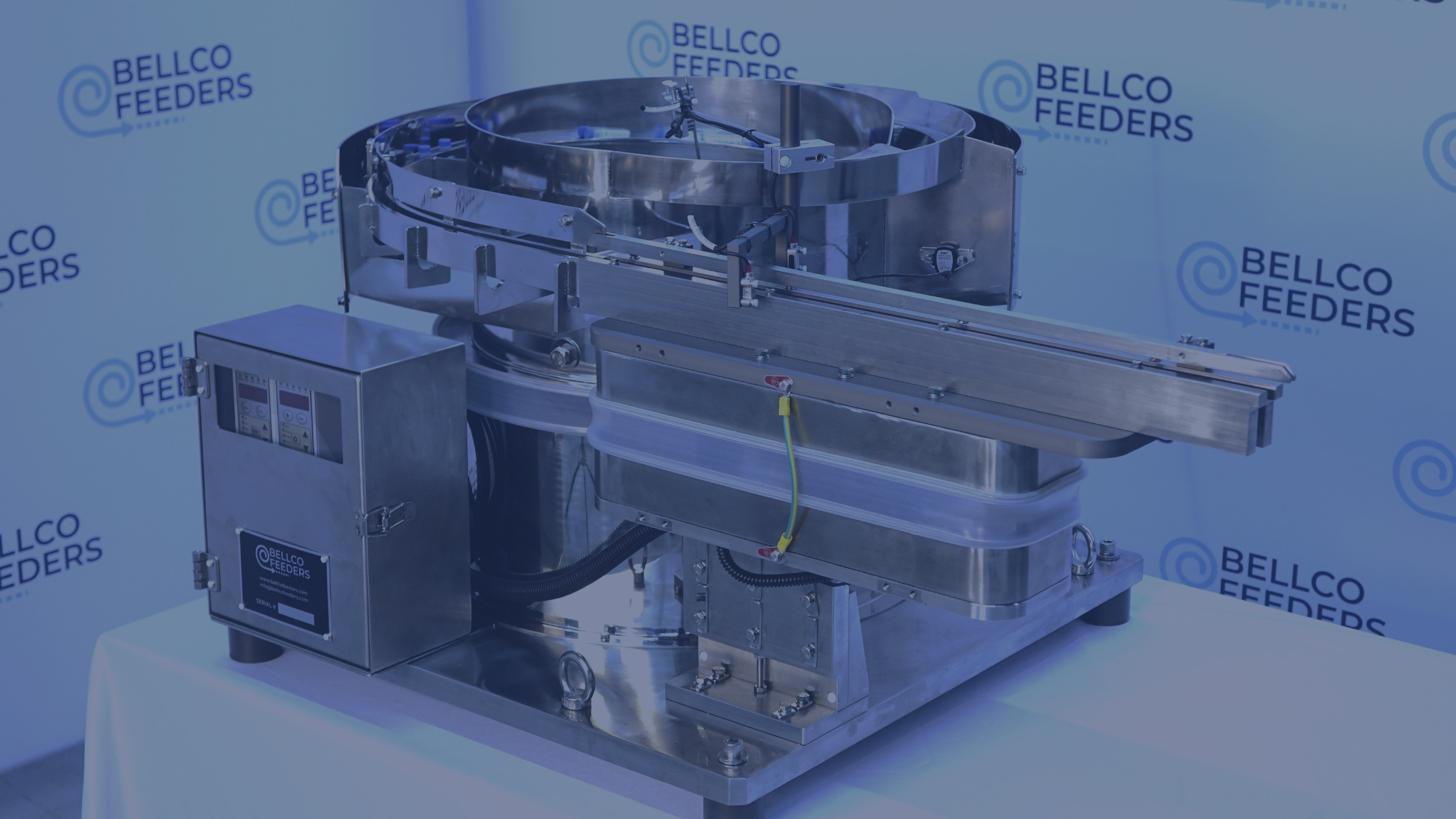

Typically, a vibratory bowl feeder consists of a bowl (the feeder) that is equipped with a base that vibrates. As the bowl vibrates, it causes parts to move in specific directions, sorting and orienting them to be arranged from bulk into a single file line and based on a certain orientation.

These feeders can be customized to handle a variety of parts, from tiny screws to large, heavy components, making them incredibly versatile and a cornerstone of automated production systems. The vibratory action allows parts to be conveyed, separated, and oriented in a way that simplifies the assembly process.

The Mechanics Behind the Magic

The process behind vibratory bowl feeders relies on the primary principles of vibration and gravity. The bowl is placed on a set of springs or a base that generates vibrations. These vibrations are transferred to the parts in the bowl, causing them to move in specific patterns. The geometry of the bowl and the type of vibrations are designed to help parts move towards the desired exit point, where they are ready to be picked up and further processed or assembled.

Through this efficient sorting and orienting process, vibratory bowl feeders drastically reduce manual labor, making production lines faster, more precise, and safer. The feeders can handle a wide range of parts, including those that need to be oriented in a specific direction for downstream processes like assembly, testing, or packaging.

How Vibratory Bowl Feeders Revolutionize Manufacturing

| Increased Efficiency | Vibratory bowl feeders streamline the feeding process, allowing manufacturers to run automated systems continuously without the need for manual sorting. This not only speeds up production but also reduces downtime, leading to improved overall efficiency. | |

| Enhanced Precision | With the ability to sort and orient parts automatically, vibratory bowl feeders ensure that parts are delivered in the correct orientation and sequence every time. This reduces the risk of errors and improves the quality of the final product. | |

| Cost Savings | By automating parts feeding, manufacturers can significantly cut labor costs and reduce the likelihood of human error. Additionally, vibratory bowl feeders are highly reliable and require minimal maintenance, further contributing to cost savings in the long run. | |

| Customization for Unique Needs | Vibratory bowl feeders can be customized to meet the specific needs of a manufacturer’s operations. Whether you're working with small, delicate components or larger, heavier parts, vibratory bowl feeders can be designed to accommodate a wide range of materials and part types. | |

| Improved Safety | By automating the parts feeding process, the risks associated with manual handling are minimized, which enhances workplace safety. Parts that might have been previously difficult or hazardous to handle manually can now be easily managed by the feeder system. | |

| Integration with Other Automation Systems | Vibratory bowl feeders integrate seamlessly into larger automated systems, such as robotic arms, conveyors, and assembly machines. This enables manufacturers to create fully automated, streamlined production lines, further improving speed, efficiency, and cost-effectiveness. |

Industries Benefiting from Vibratory Bowl Feeders

Vibratory bowl feeders are used across a broad range of industries, including:• Automotive – For feeding small parts like screws, nuts, and bolts into assembly lines.

• Electronics – Handling components like capacitors, resistors, and connectors.

• Pharmaceuticals – Ensuring the accurate feeding of tablets, capsules, and medical devices.

• Consumer Goods – For packaging and assembly of products like cosmetics, toys, and household items.

Conclusion

Vibratory bowl feeders are a game-changing technology for modern manufacturing. By automating the parts feeding process, they not only increase efficiency and precision but also contribute to cost savings and improved safety. With their ability to handle a wide range of parts and integrate into larger automation systems, vibratory bowl feeders are essential for manufacturers looking to optimize their operations and stay competitive in a fast-evolving market.

At Bellco Feeders, we specialize in designing and manufacturing custom vibratory bowl feeders and custom step feeders to solve the unique challenges faced by our clients in the manufacturing and automation industries. If you're looking to improve your parts feeding systems and boost your production efficiency, contact us today to learn more about our solutions.