In the fast-paced world of ammunition production, efficiency is key. And when it comes to ensuring a seamless and continuous process, vibratory bowl feeders play an essential role. These bowl feeders provide a reliable and efficient way to handle and orient small components with precision. See how and why vibratory bowl feeders play a crucial role in ammunition production and why they are vital in keeping operations running smoothly.

The Importance of Efficient Manufacturing Practices for Ammunition Production

Efficient manufacturing practices in ammunition production are crucial for ensuring the timely and reliable supply of high-quality ammunition, which is vital for national security and defense operations. Streamlined processes reduce costs and waste, enhancing economic sustainability and environmental responsibility. Moreover, precision and consistency in manufacturing are essential to maintain the safety and performance of the ammunition, thereby safeguarding military personnel and optimizing operational effectiveness. By adopting advanced technologies and continuous improvement strategies, manufacturers can meet the increasing demands and stringent standards of modern defense requirements.

Vibratory bowl feeders play a pivotal role in streamlined production, in the ammunition industry and beyond, by efficiently sorting and feeding small parts and components in a precise, consistent manner. Their ability to handle a high volume of items with minimal human intervention reduces bottlenecks and increases overall production speed. By automating the orientation and positioning of parts, these feeders enhance accuracy and minimize errors, leading to higher-quality output. Vibratory bowl feeders are also highly versatile and can be easily integrated into various stages of the production process, further optimizing workflow and boosting productivity.

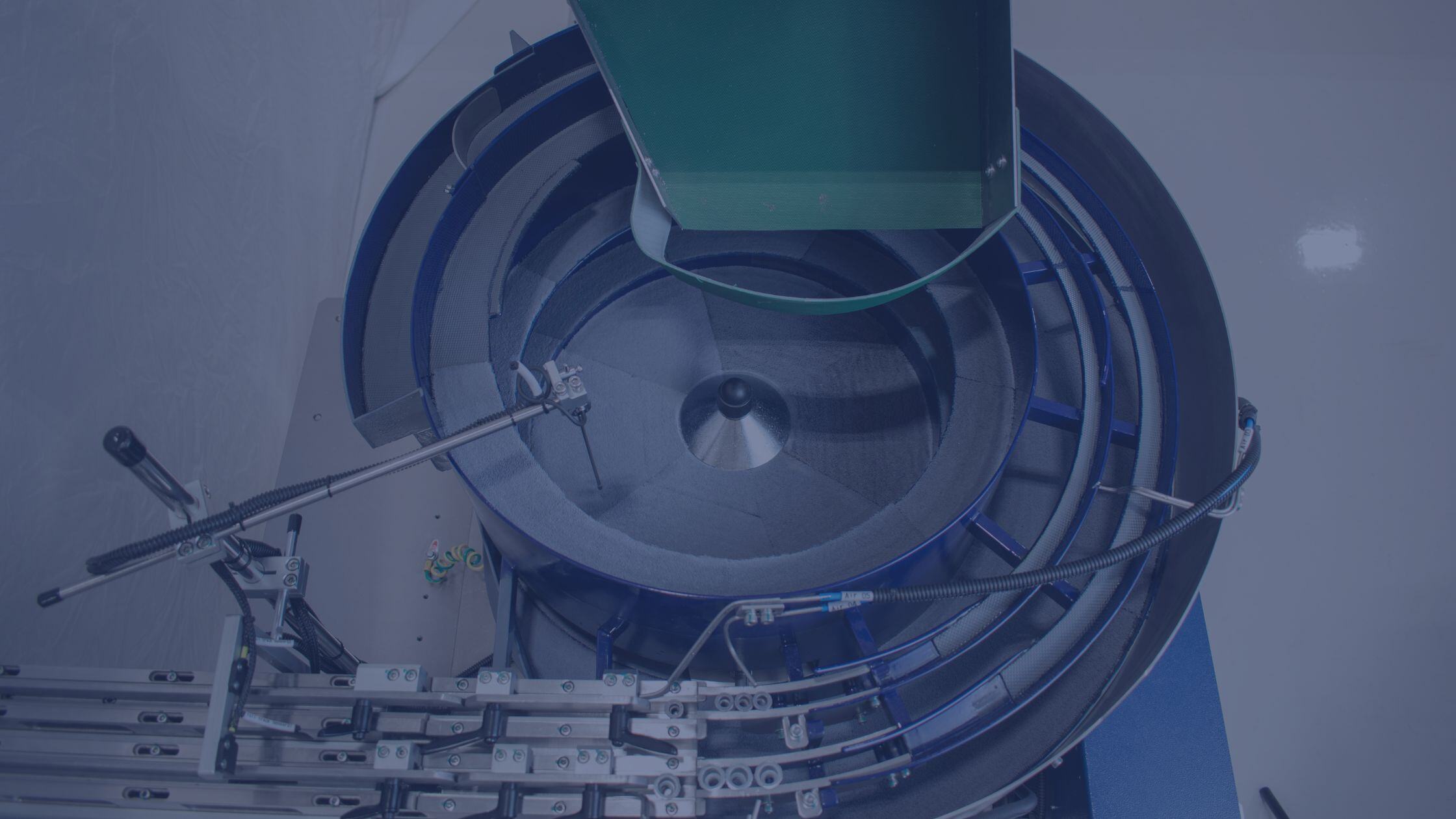

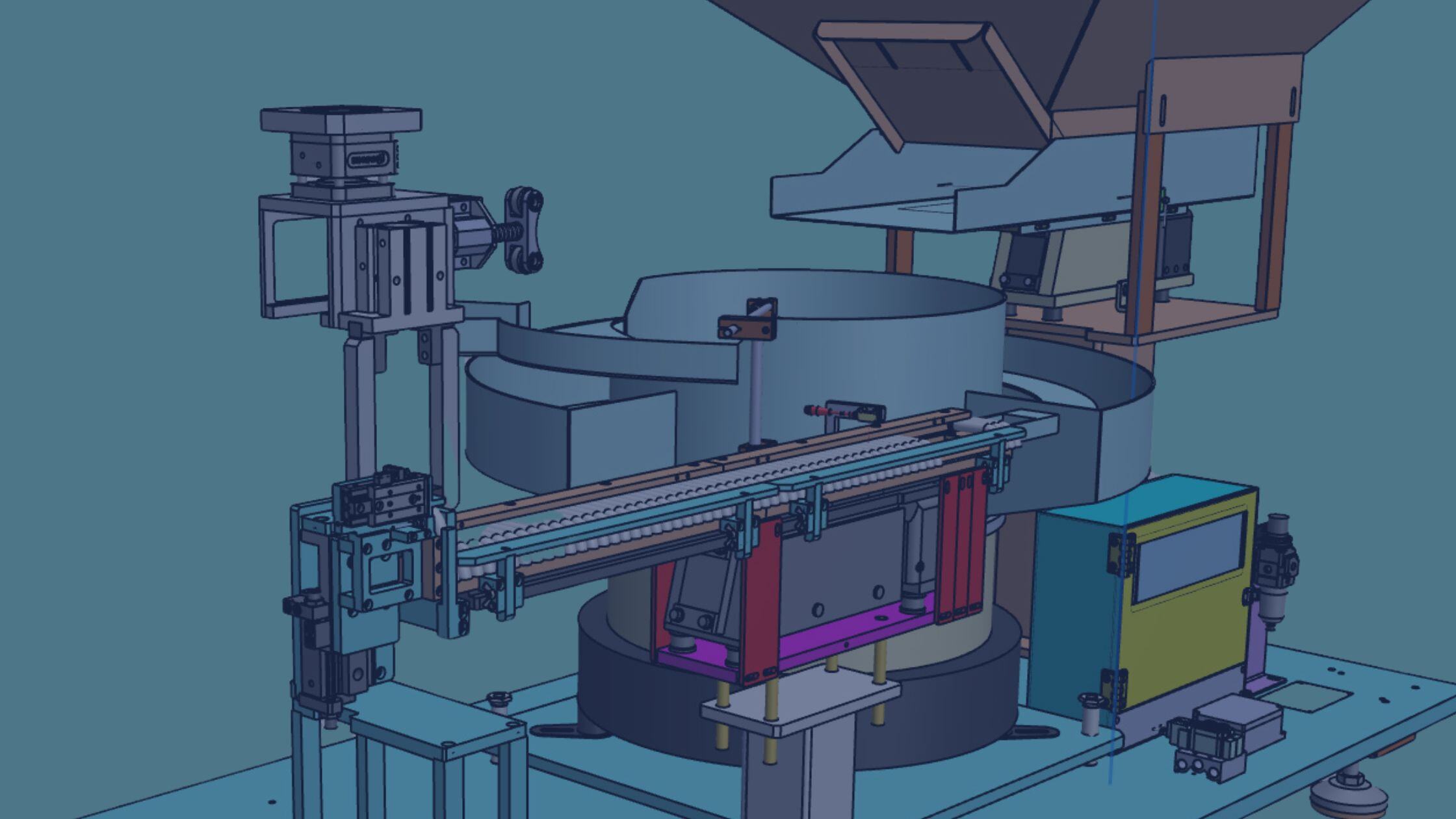

Bellco designed a vibratory bowl feeding system to feed M9 links used to hold ammunition for machine guns

What role do Vibratory Bowl Feeders play in the Ammunition Industry?

Vibratory bowl feeders play a crucial role in the ammunition industry by efficiently sorting and orienting small parts used in manufacturing ammunition. These high-speed feeders use vibration to move components along tracks, ensuring smooth and continuous production processes.

In the ammunition industry, efficient manufacturing is key to ensure the quality and consistency of each round produced. Vibratory bowl feeders help maintain this precision by accurately aligning bullet casings, primers, and other components before they are assembled into cartridges.

By using vibratory bowl feeders, manufacturers can significantly increase their production output while minimizing errors and defects. These automated systems reduce manual labor requirements and streamline the assembly process, leading to higher efficiency and cost savings for ammunition producers.

Main Advantages of Using Vibratory Bowl Feeders in Ammunition Production

Versatility and Adaptability: One of the main advantages of using vibratory bowl feeders is their ability to handle a wide range of part sizes and shapes with ease. This flexibility allows for seamless integration into various stages of the ammunition manufacturing process, from sorting tiny components to larger pieces.

Efficiency and Cost Savings: Vibratory bowl feeders help streamline production by automating the feeding process, increasing efficiency, and reducing manual labor requirements. By optimizing part orientation and alignment, these feeders contribute to higher output rates while maintaining product consistency.

Reducing Waste and Improving Quality: In ammunition manufacturing, even the slightest flaw can be problematic. Vibratory bowl feeders play a crucial role in minimizing waste and improving quality by ensuring consistent feeding and assembly of components. By reducing misfeeds, jams, and inconsistencies, they help eliminate defects and rejects, ultimately enhancing the overall quality of the ammunition.

Overall, incorporating vibratory bowl feeders into ammunition production not only enhances accuracy but also boosts productivity levels, making them indispensable tools in modern manufacturing facilities aiming for precision and efficiency in their operations.

Challenges and Solutions for Implementing Vibratory Bowl Feeders in the Ammunition Industry

Implementing vibratory bowl feeders in ammunition production comes with its own set of challenges. One common issue is ensuring that the feed rate matches the required production speed to meet demand without causing jams or errors in parts sorting. To overcome this challenge, manufacturers can fine-tune the settings of the vibratory bowl feeder to achieve optimal performance.

Another challenge is maintaining cleanliness and preventing contamination when handling sensitive or hazardous materials used in ammunition manufacturing processes. Regular cleaning and inspection of the vibratory bowl feeder components are essential to ensure smooth operation and product quality.

In terms of solutions, investing in high-quality vibratory bowl feeders designed specifically for ammunition production can significantly reduce downtime and increase efficiency. Working closely with experienced suppliers who understand the unique requirements of the industry can also help address any technical issues quickly and effectively.

By staying informed about emerging trends and innovations in vibratory bowl feeder technology, ammunition manufacturers can stay ahead of the competition while meeting strict quality standards. With careful maintenance, strategic implementation, and a proactive approach to challenges, vibratory bowl feeders play an essential role in enhancing precision and efficiency in ammunition production processes.

Conclusion

Vibratory bowl feeders are essential tools for achieving high levels of precision and accuracy in ammunition manufacturing. Their ability to efficiently sort parts not only streamlines production but also ensures that every bullet or shell meets the strict standards required for safety and performance. By integrating vibratory bowl feeders into their operations, ammunition manufacturers can enhance productivity, reduce waste, and deliver top-notch products to meet market demands effectively.