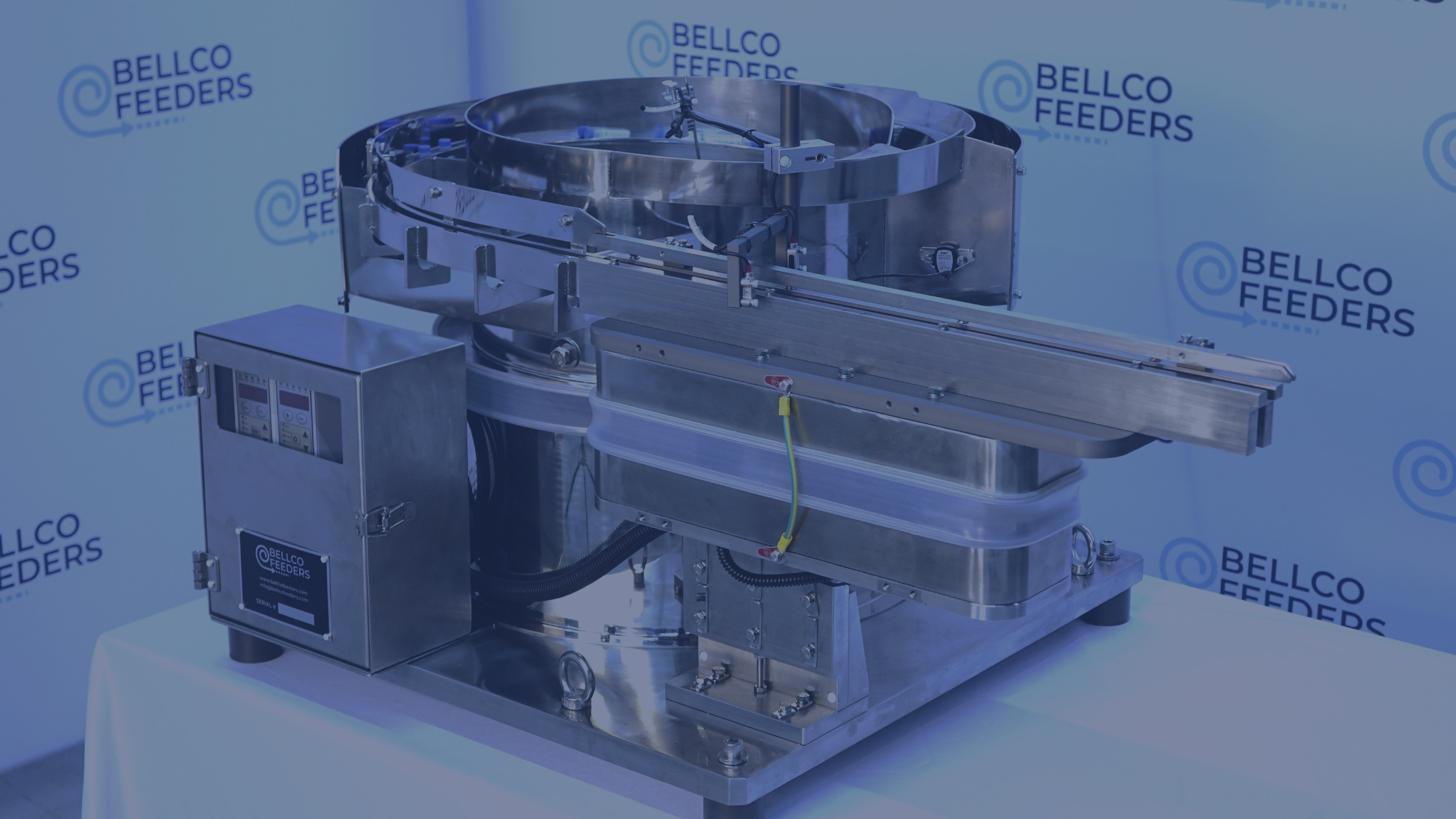

Case Study: 316 Stainless Steel Tablet Parts Feeding System

| Industry: Medical and Pharmaceutical | |

| Rate: 40 parts per minute (20ppm per escapement) | |

| Hopper Capacity: 2 hours unassisted run time | |

| Components: Vibratory Bowl Feeder with Low Profile Hopper, Vibratory In Line Track, and Dual Track Escapement |

Project Overview

A pharmaceutical packing company approached Bellco with the need for an automated solution to feed fragile tablets efficiently and gently into a blister packaging system. The challenge was to design a system capable of feeding tablets from a hopper, around a bowl, and down an escapement without damaging the tablets.

Bellco faced several significant challenges in developing this automated feeding system:

- Gentle Parts Feeding: Ensuring fragile tablets could flow freely and without damage throughout the feeding process was critical.

- Material Certifications: The pharmaceutical company required strict compliance with material certifications, demanding that all components in contact with the tablets meet specific standards.

- Precise Singulation: The system had to consistently singulate the tablets at specific intervals for accurate placement in the blister packs.

- 316 Polished Stainless Steel: All components needed to be constructed from 316 polished stainless steel, with all welds filled and ground to ensure a smooth finish that would not compromise the tablets.

- Dust Collection: The tablets tended to generate powder during handling, necessitating a dust collection system to maintain a clean environment and ensure consistent feeding.

To address these challenges, Bellco’s engineering team implemented several innovative solutions:

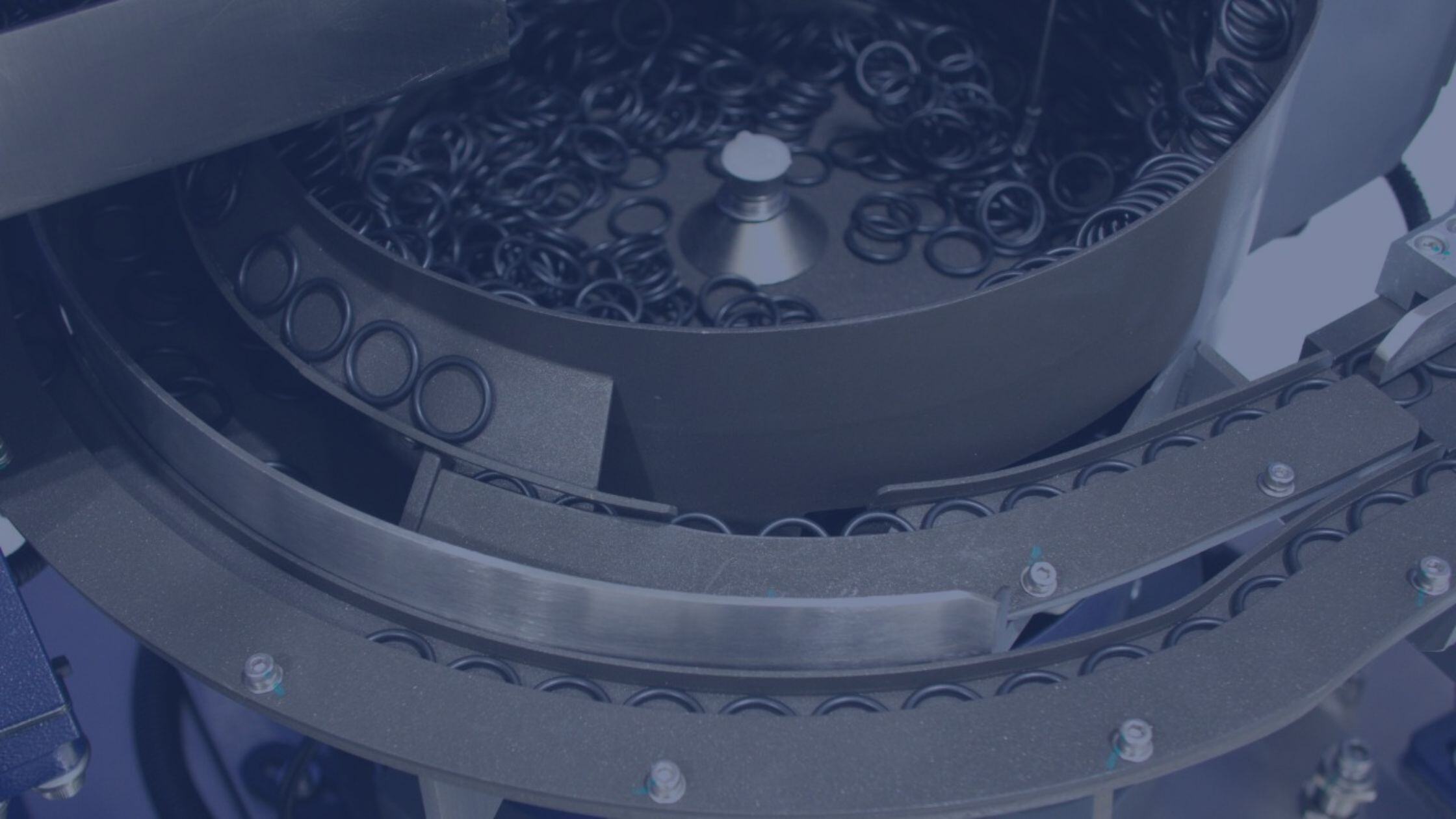

Low Profile HopperRecognizing the fragility of the tablets, Bellco designed a low-profile hopper that allowed tablets to gently fall into the feeder bowl with minimal distance, significantly reducing the risk of breakage. A custom cutout section in the bowl ensured that the hopper fit seamlessly within a two-inch gap. |

|

Material CertificationsUnderstanding the customer’s emphasis on compliance, Bellco committed to providing comprehensive material certifications with all parts in contact with the tablets. This documentation is included in Bellco's standard documentation package, assuring the customer of compliance with their specifications. |

|

Dual Track EscapementBellco engineered a dual track escapement system capable of dispensing two tablets simultaneously at precise intervals. This was achieved using two solenoids that operated in sync, opening and closing to control the release of each tablet, ensuring consistent spacing. |

|

Dust/Powder CollectionTo combat the issue of powder accumulation from the tablets, Bellco designed a dedicated powder collection area within the feeder bowl. Holes were integrated into the bowl to allow the tablets to move freely while simultaneously capturing powder in a bin located underneath, ensuring a clean and efficient feeding process. |

|

Key features our team included to ensure proper functionality:

Auto Vibration Sensor: Various sensors were strategically placed throughout the system to optimize performance.

Two Finger Escapement: Two fiber optic sensors in the hopper provided visual cues to operators, indicating when parts were running low or when the hopper was adequately stocked.

The Results

The successful implementation of this automated tablet feeding system significantly improved the efficiency and reliability of the pharmaceutical packing process. The gentle handling of fragile tablets minimized breakage, while the precise singulation and effective dust collection contributed to higher product quality and a cleaner operational environment. Additionally, compliance with material certifications ensured that the system met the stringent requirements of the pharmaceutical industry.

Conclusion

Bellco's innovative approach to solving the challenges faced by the pharmaceutical packing company demonstrates their commitment to quality and customer satisfaction. Through collaboration, engineering expertise, and a focus on compliance, Bellco delivered a tailored solution that enhanced the company's operational capabilities.