Case Study: Cap and Vial Vibratory Feeder Bowls Made From 316 Stainless Steel

| Industry: Medical & Pharmaceutical (316 Polished Stainless Steel) | |

| Rate: Cap Bowls 30ppm / Vial Bowl - 30ppm (Per Track) / Assembled Vial - 75ppm | |

| Escapement: Cap Bowls - Dead Nest / Vial Bowl - Vacuum Generator Dual Lane |

Client Overview

A leading pharmaceutical packaging company sought a solution to enhance its in-house dial packaging machine’s feeding system. The client approached Bellco to design and implement a tailored feeding system that would efficiently handle vials, caps, and assembled vials. Specifically, Bellco was tasked with creating three separate systems: one for vials, one for caps, and a third to feed assembled vials. The feeding systems needed to comply with strict material certification requirements due to their direct interaction with medical products.

Project Overview

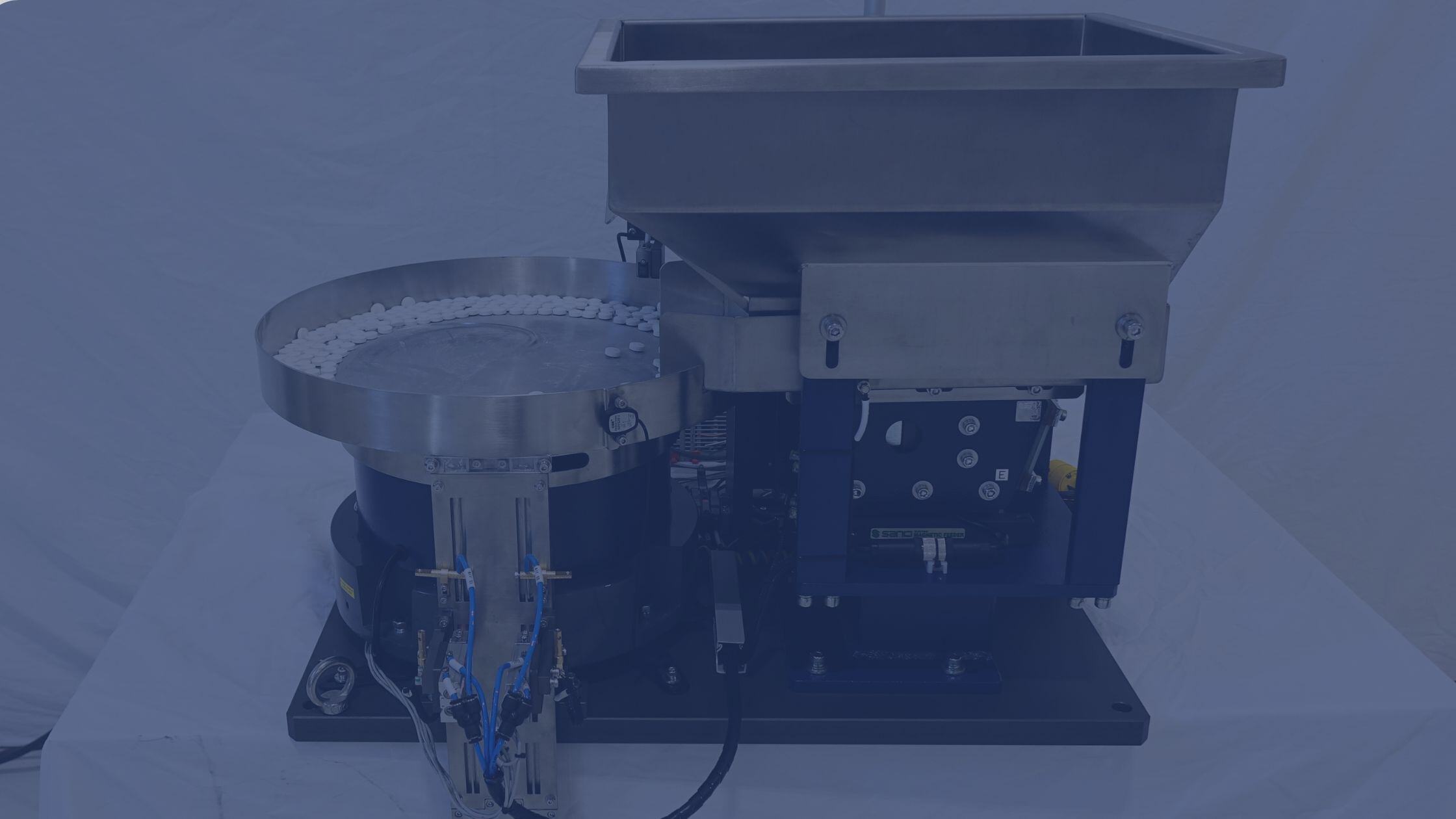

The project’s main objective was to increase production rates while optimizing space and maintaining efficiency in the client’s manufacturing process. Bellco was selected for the project due to its expertise in designing multilane feeders that could meet the increased production demands while minimizing the required floor space. The scope of the project included the design and development of three systems:

- A dual-lane system for vials.

- A two-bowl system for caps.

- A third system to feed assembled vials into the final packaging cell.

-1.jpg?width=1200&length=1200&name=Both%20Bowls%20(Best)-1.jpg)

%20(Best)-1.jpg?width=1200&length=1200&name=Close%20Up%20of%20Cap%20Tooling%20(With%20Part)%20(Best)-1.jpg)

-3.jpg?width=1200&length=1200&name=Bowl%20View%20(Best)-3.jpg)

.jpg?width=1200&length=1200&name=Both%20Linear%20Tracks%20(Filled).jpg)

-1.jpg?width=1200&length=1200&name=shared%20image%20(2)-1.jpg)

Design Phase:

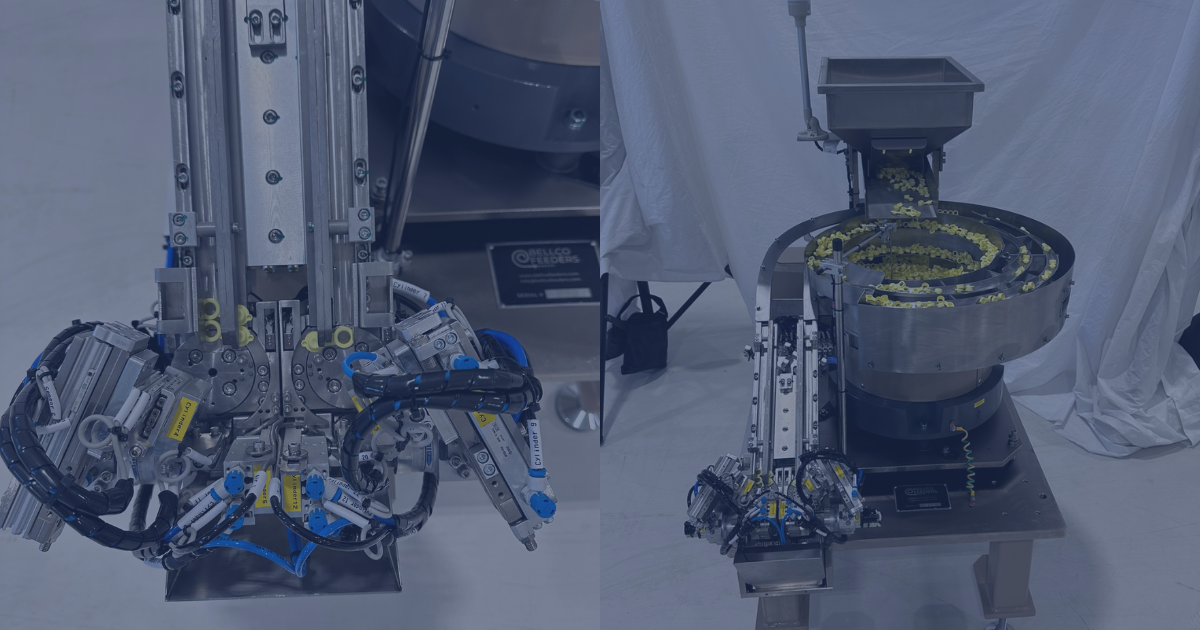

Vial Bowl Design:

|

|

Cap Bowl Design:

|

-1.jpg?width=296&height=408&name=Bowl%202%20(Entire%20Bowl)-1.jpg) |

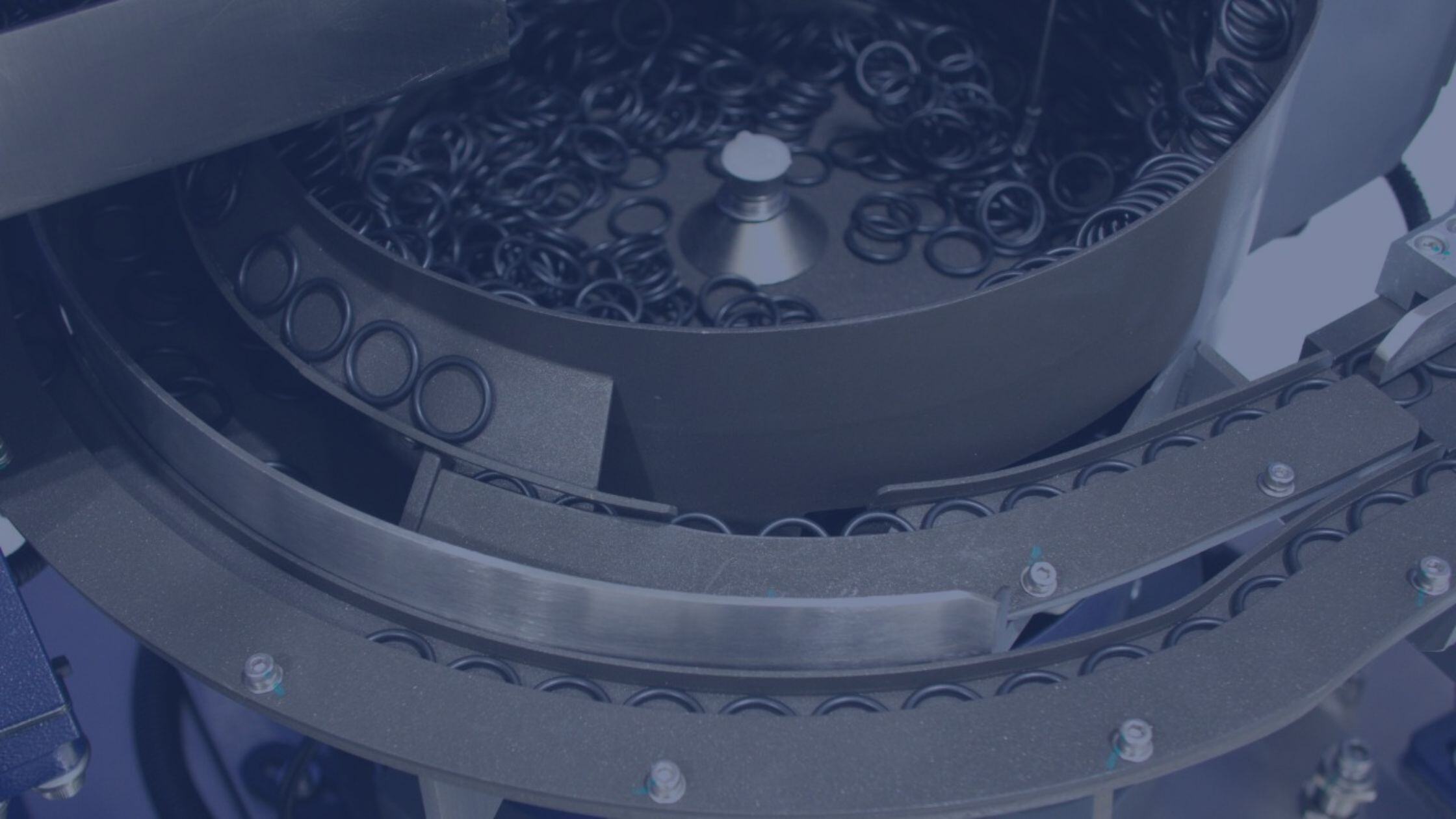

Assembled Vial Bowl Design:

|

|

Precision Manufacturing and Integration:

Bellco's ability to seamlessly integrate custom-designed feeding systems with the client's existing machinery was key to the project’s success. Using SolidWorks, the engineering team designed each feeding system with perfect alignment to the client’s dial packaging machine. Before production began, Bellco provided the customer with a step file for review to ensure the system would fit within their existing setup. No manufacturing proceeded without the client’s approval of the design, ensuring alignment with their needs and expectations.

Run-off and Final Approval:

To ensure the system's functionality, Bellco recommended that the client visit their facility in Concord Township, Ohio, for a live demonstration. For clients unable to attend in person, Bellco offered live video run-offs to provide real-time performance visibility. For this project, Bellco conducted a 2-hour live video run-off. Upon approval, the system was shipped to the client within 12 weeks from project initiation.

Conclusion:

Bellco's successful implementation of the dual-lane feeding system for vials, caps, and assembled vials demonstrates the company’s expertise in meeting complex challenges within the pharmaceutical packaging industry. The innovative designs provided the client with increased production rates, improved efficiency, and a compact system that maximized floor space. The collaboration between Bellco's engineering team and the client ensured that the final system met all requirements and certifications, demonstrating Bellco’s commitment to precision and quality.

Bellco remains a trusted partner for companies looking to optimize their manufacturing processes, combining cutting-edge design, precision engineering, and exceptional customer service.

-1.jpg?width=331&height=442&name=shared%20image%20(3)-1.jpg)