| Industry: Appliance | |

| Rate: 20ppm per track (40ppm total) | |

| Hopper Capacity: 30 minute run time | |

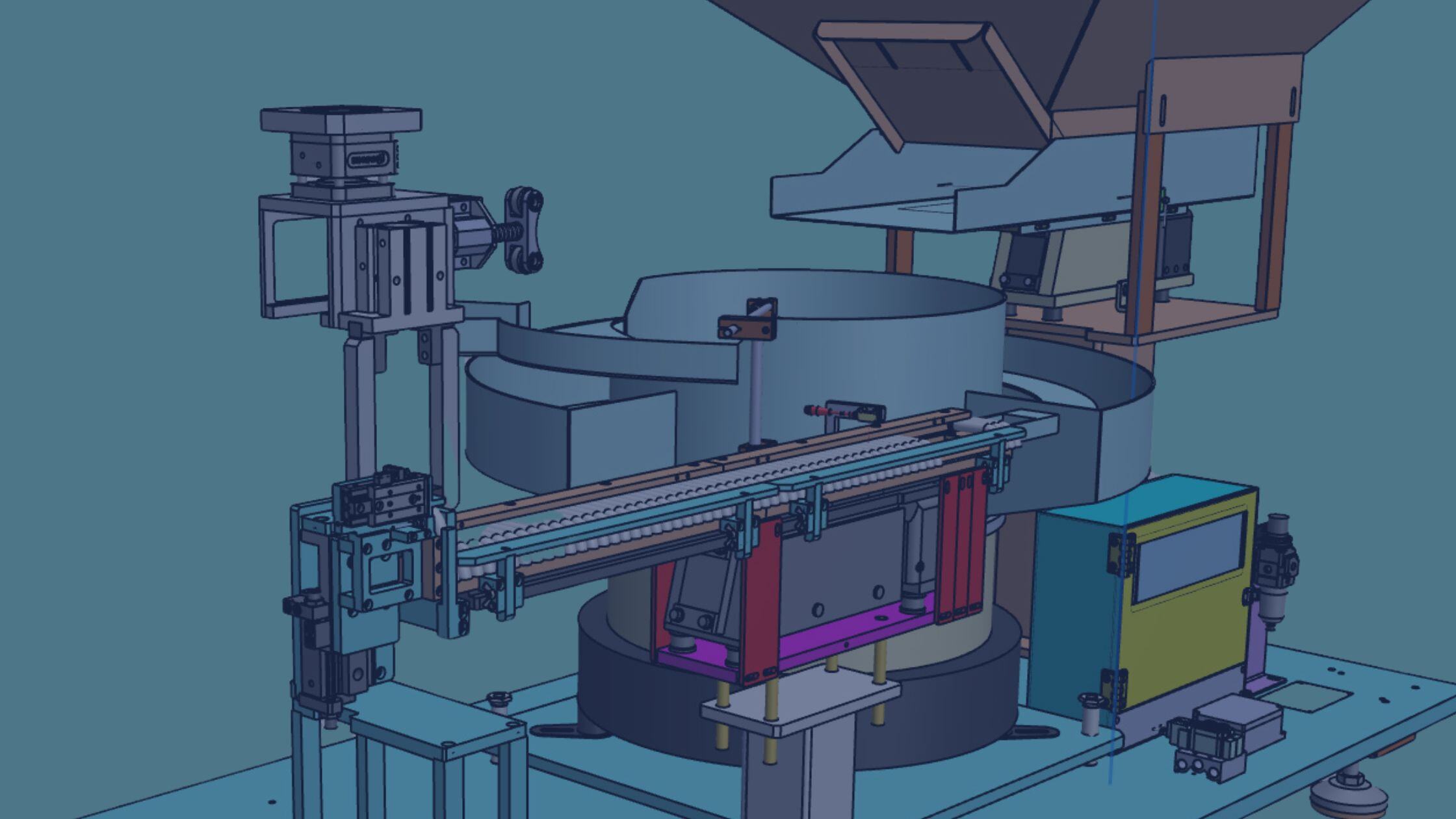

| Components: Vibratory Bowl Feeder with Hopper, Dual Linear Track System, Full Track Sensors |

About The Project

An original equipment manufacturer (OEM) sought to replace two outdated parts feeding systems and approached Bellco Feeders to redesign and replace their existing setup. The OEM required the new systems to seamlessly integrate with their current machinery without necessitating any modifications on their end.

Our customer's needs:

The customer's primary requirement was for an O-ring parts feeding system with a footprint matching their previous systems. Additionally, they needed integration with their current machinery. An essential feature was the inclusion of a hopper system that would enable operators to leave the bowl unattended for up to 30 minutes continuously.

Challenges our team faced during this project:

Bellco faced a significant challenge in designing a single bowl with a dual linear track. This track needed to align precisely with the current escapement, requiring precise height adjustment of the bowl

Results:

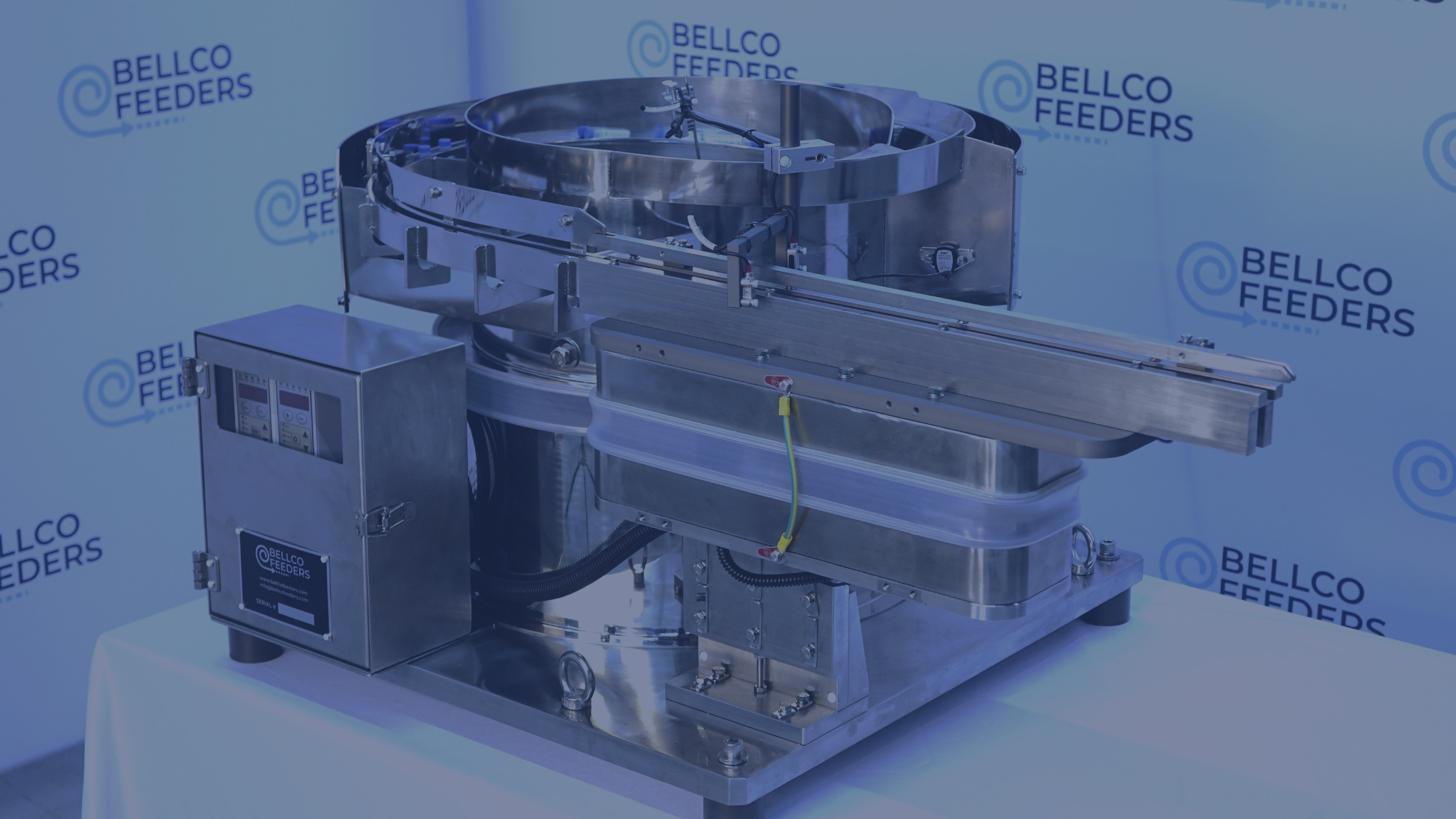

Bellco Feeders successfully developed a comprehensive system meeting all customer requirements. The delivered system comprised a bulk parts hopper, a vibratory feeder bowl, a vibrating dual linear track, and intelligent digital controllers.

Final Details

- Bellco's engineers designed a parts feeding system equipped with a hopper allowing for over 30 minutes of continuous operation. The hopper automatically activates and deactivates based on communication with a parts shortage sensor within the bowl feeder, maintaining the optimal number of parts for efficient operation. A stack light indicator alerts operators when additional parts need to be added.

- Two identical bowls were implemented to feed O-rings at a rate of 40 parts per minute (ppm). Bellco applied a specialized coating to these bowls, ensuring smooth movement of the O-rings within.

- A dual linear track system was designed and executed, running off a single drive unit. This system facilitated two exit points from the feeder bowl onto a single linear track, with each pathway featuring full track sensors to control the flow of parts. The bowl shuts off when the linear track is full and resumes operation once the O-rings clear the sensors.

- Bellco's solution exceeded the client's expectations through the use of high-quality materials, advanced electronics, and cost-effective design strategies.