| Industry: Medical + Life Sciences | |

| Rate: 150 parts per minute | |

| Hopper Capacity: 30 minute run time | |

| 4 Identical Parts Feeding Systems Produced |

About The Project

A medical start-up company needed to increase manufacturing capacity on a new version of their top-selling product, an FDA-approved medical device. A revision in the product line required a cost-effective and precise solution that would feed metal washers into a high-speed automated machine.

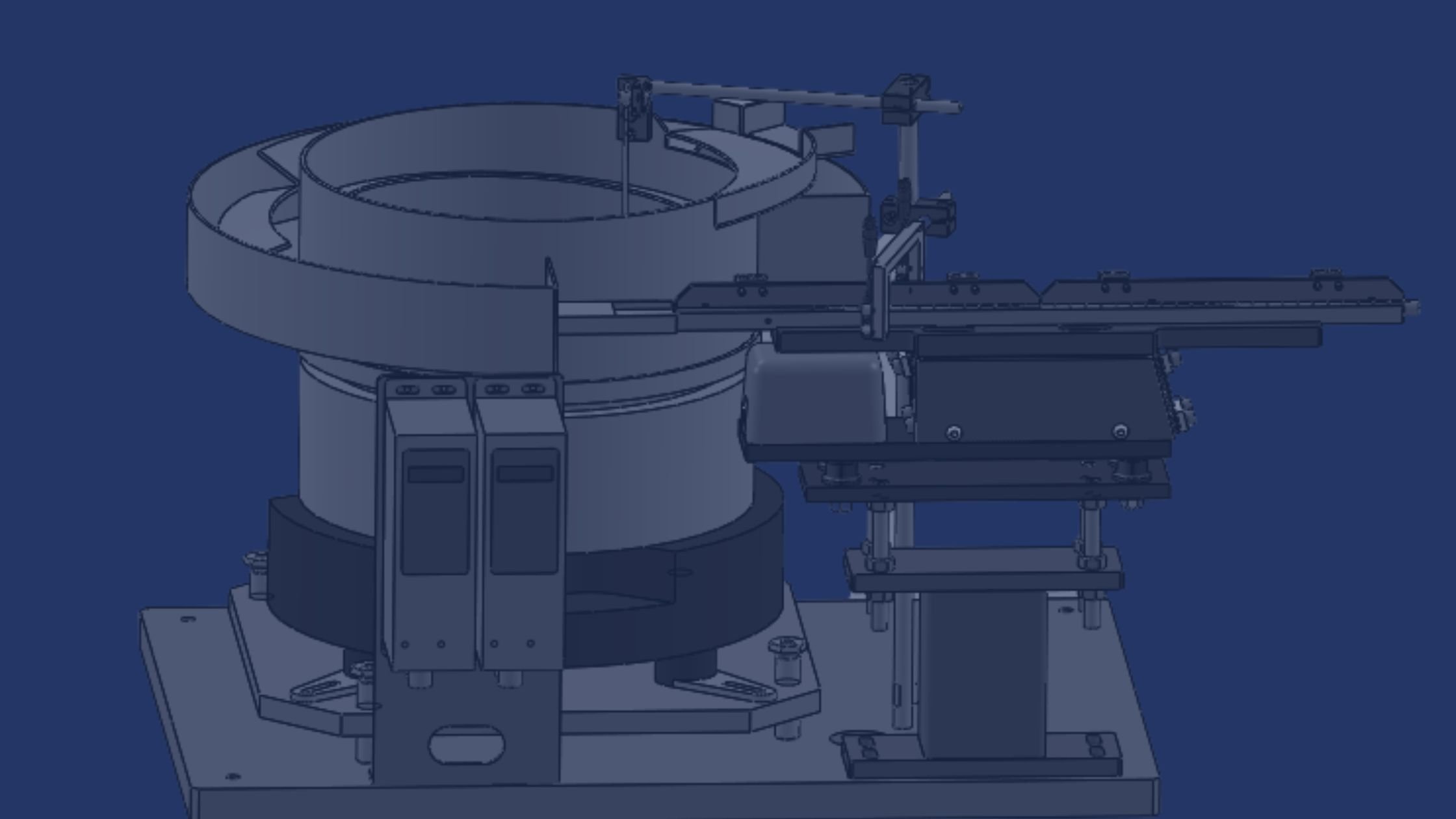

Bellco provided four identical vibratory bowl feeders that for integration into an automated machine. Two bowl feeders on each side operated simultaneously to achieve an overall rate of 480 parts per minute (120 parts per minute per bowl).

Customer need:

With a small footprint, a high throughput required, and fewer operators available to maintain the system, this customer required a fully automatic solution.

Project challenges:

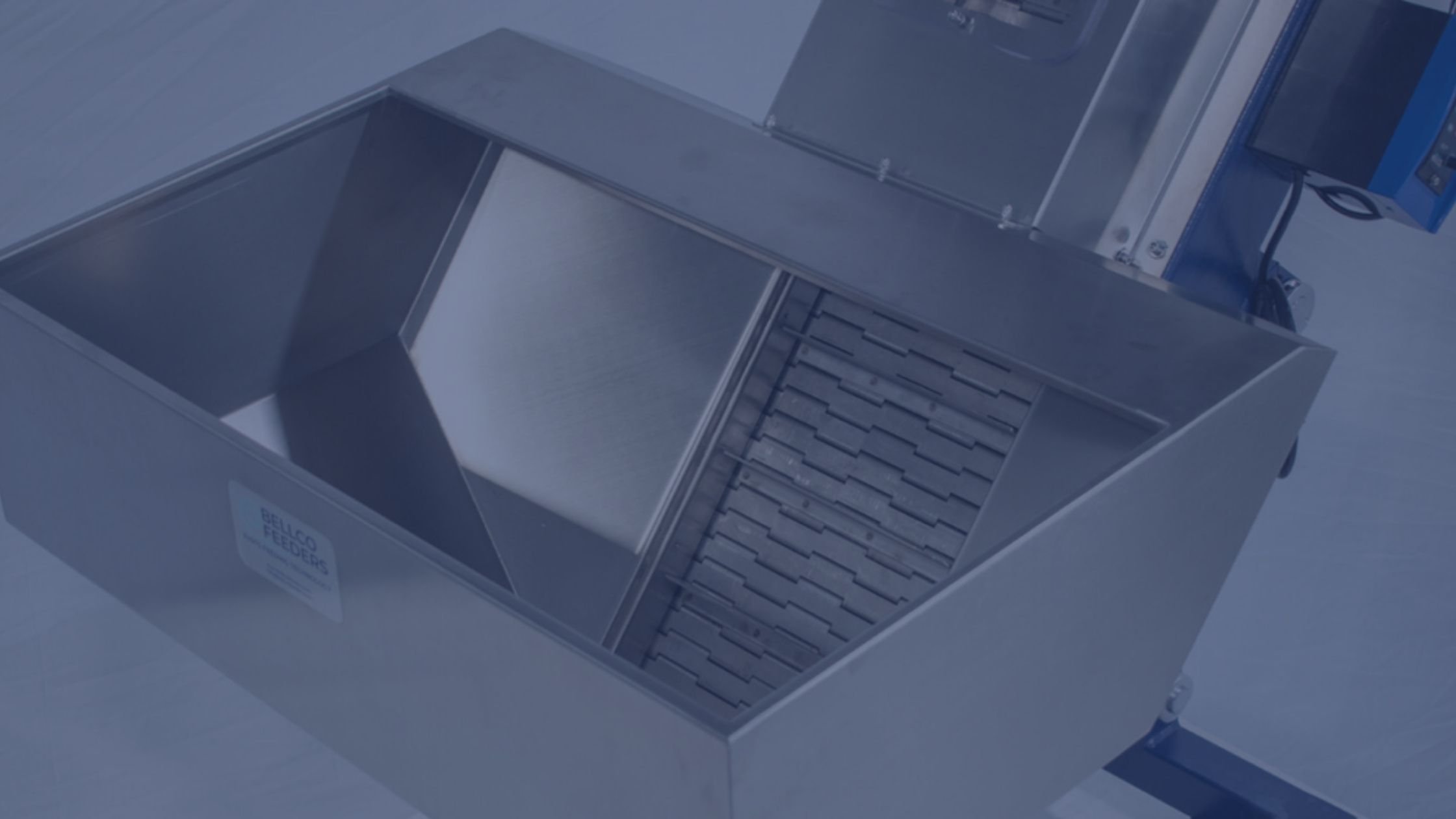

To ensure the required throughput, Bellco’s engineering team precisely calculated the linear track length necessary to maintain consistent part feeding to the machine, while carefully considering weight constraints. Adding hoppers was also a vital part of the project to guarantee the efficient operation of the bowl feeders while monitoring the metal washer count and weight.

Results:

Bellco's engineering team was able to design four vibratory bowls - each with a long linear track to allow the metal washers to be collected. The parts accumulation created a buffer that allowed the bowls to operate consistently at a high-speed rate.

The Final Details

Since the bowl feeders were in pairs, and the parts needed to be delivered to the machine close together, one bowl of each set turned counter-clockwise, the other clockwise. The linear feeders ran parallel. A custom air-assisted guide track allowed precise feeding and guided the parts throughout the system.

Bellco also added bulk part hoppers on each feeder bowl to hold extra metal washers and monitor their count. Overloaded bowls are heavy and will not operate efficiently - the hoppers control and add more parts as needed. As a result, the machines can be loaded by the operator and left unattended.

Bellco delivered a tailored, high-precision solution that fulfilled the client’s requirements within a demanding project timeline. Our team achieved a streamlined six-week delivery, ensuring the vibratory bowl feeders operated reliably and were seamlessly integrated into the client's medical device assembly line. Leveraging our video approval process, we facilitated rapid client sign-off and expedited shipment, underscoring Bellco’s commitment to responsive, high-quality customer service.