| Industry: Manufacturing | |

| Rate: 20 parts per minute | |

| Hopper Capacity: 30 minute unattended run time | |

About The Project

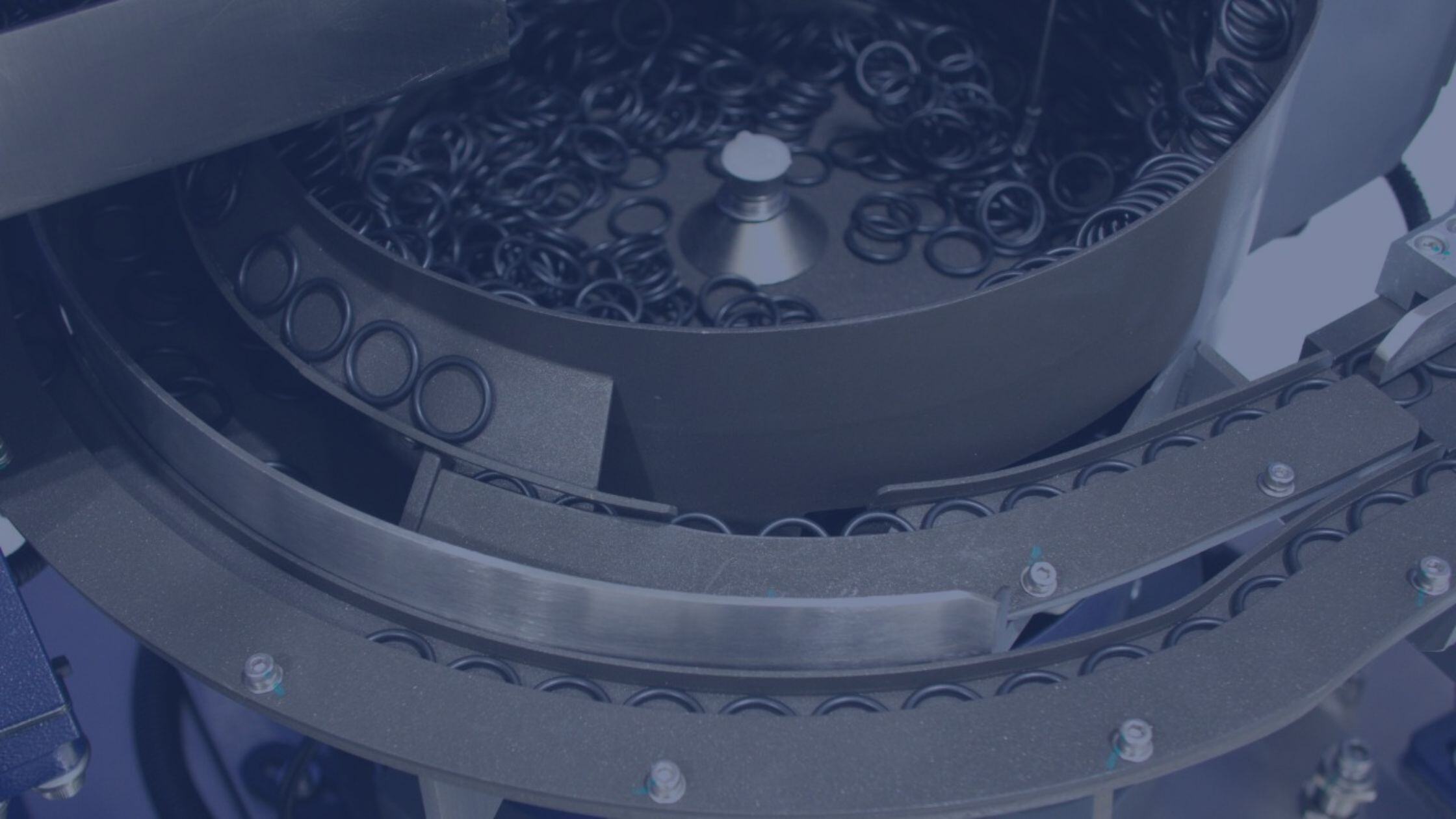

An OEM building an automated machine for a customer in the manufacturing industry requested a bowl feeder with hopper for a metal housing.

The bowl needed to operate in a counter clockwise orientation and have a linear track to present parts one at at time to the automated machine.

Customer Need:

Our customer needed an automated solution for feeding metal housings from bulk. The system needed to incorporate legs so that the linear track was at the correct height to level with their automation machine.

Project Challenges:

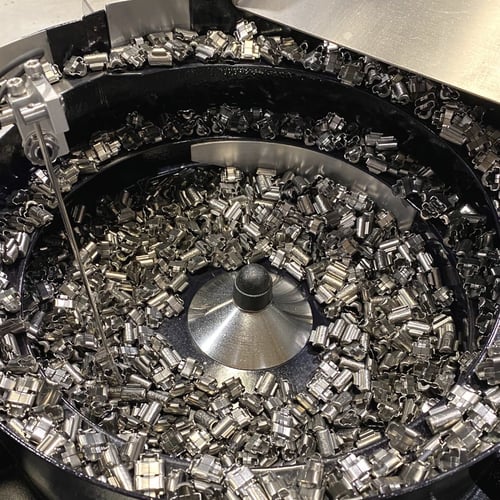

This project was pretty straight forward; the Bellco team designs and manufactured many metal parts feeding bowls. Because of the weight and geometry of the parts, we knew that designing a robust system to withstand a manufacturing environment was important.

Results:

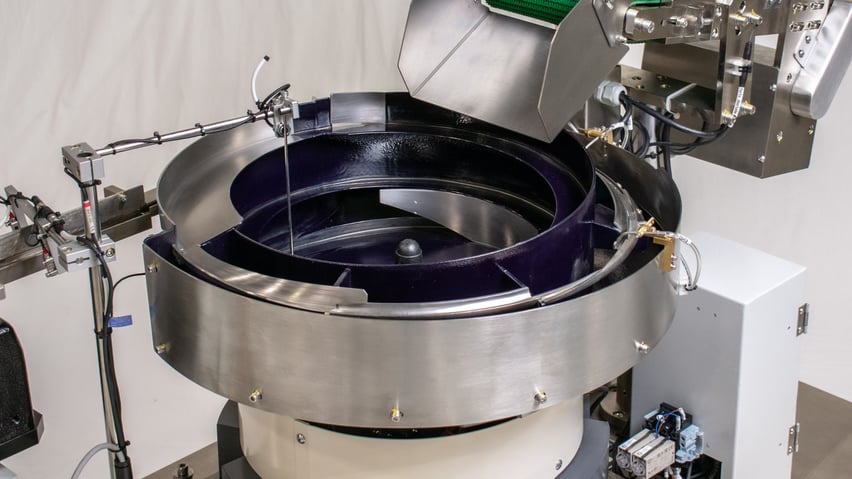

Bellco Feeders delivered a complete parts feeding system which consisted of a bulk parts hopper, a vibratory feeder bowl, and a vibrating linear track.

Final Details

Our engineers designed an automatic parts feeding systems that allowed the operators to leave the feeder unattended for up to 30 minutes. The bowl feeder had a parts shortage sensor to notify the hopper to add more parts. We integrated a stack light to notify the operators when the bowl needed more parts added. We designed the linear feeder complete with it's own drive and controller to ensure accurate and consistency in moving the parts down the track.

Our expert feeder bowl craftsmen's made sure no attention to detail was spared in the construction and testing of the bowl. Each screw is double checked for the correct torque and marked for consistency.

The final system incorporated many features that we includes in our standard feature package including:

- Variable frequency digital intelligent controllers which provide quick and easy adjustments to the vibrations that power the feeder

- 1 inch nickel plated steel baseplate that is design to provide optimal vibration dampening to ensure the bowl is operative at the maximum efficiency

- A complete FESTO air-prep unit with SMC valves, air tubing and regulators to assist in moving parts along the feeder bowl tracks