| Industry: Military | |

| Rate: 150 parts per minute | |

| Hopper Capacity: 30 minute run time | |

| Components: Vibratory Bowl Feeder with Dual-Track System, Linear Track, Large Bulk Parts Hopper |

About The Project

A company approached Bellco with a challenge to automate the feeding process of M9 links in the ammunition industry, requiring a solution that could handle bulk quantities while ensuring correct orientation for seamless integration into their assembly line.

Bellco's engineering team was faced with numerous challenges during the project:

The primary hurdles included achieving high-speed feeding while ensuring accurate orientation of the M9 links and preventing tangling, given the weight and hardness of the parts. Additionally, designing a durable feeder capable of withstanding constant usage was paramount.

Solution Provided:

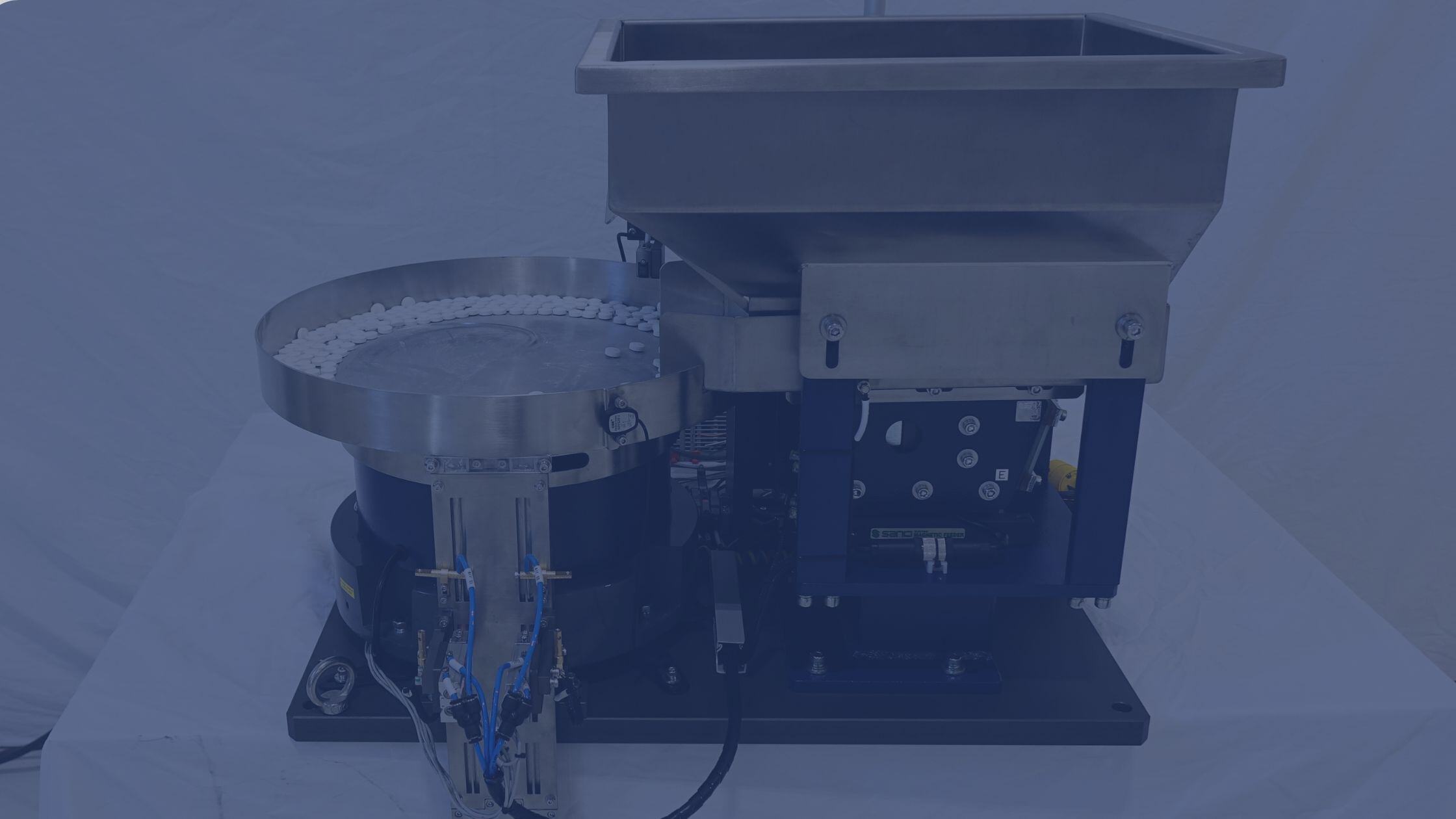

Bellco Feeders developed a comprehensive solution comprising a 30-inch vibratory bowl feeder, a 27-inch linear track, and a large, custom bulk parts hopper. The system was meticulously engineered to address the specific challenges faced by the client.

Dual Track DesignOur team devised a dual-track system within the vibratory bowl feeder, feeding into a single linear track. Custom tooling on the tracks facilitated the turning and flipping of parts to ensure correct orientation. |

|

Precision Air NozzlesPrecision-placed air nozzles, in conjunction with custom-designed tracks, aided in guiding parts along the feeder bowl tracks. Incorrectly oriented parts were automatically redirected back into the feeding process. |

|

Integrated Sensor TechnologyA vibration sensor was integrated into the feeder bowl housing, communicating with a digital intelligent controller to adjust voltage and frequency based on the weight of parts, ensuring optimal performance |

|

Automated OperationThe system was designed for unattended operation for up to 30 minutes. A level switch sensor in the hopper triggered the addition of more parts when needed, while a parts shortage sensor alerted operators via a stack light when supplies were low. |

|

Variable Frequency ControlVariable frequency digital intelligent controllers provided easy adjustment of vibrations powering the feeder. Each component—bowl, linear track, and hopper—have its own drive controlled by dedicated controllers, optimizing efficiency and performance. |

The Results

Bellco's automated M9 links feeding solution enabled our client in the ammunition industry to streamline their assembly process, eliminating manual loading and ensuring consistent part orientation. The system's reliability, durability, and automated features contributed to increased efficiency, reduced downtime, and improved overall productivity for the client.

In conclusion, Bellco's innovative approach to addressing the client's unique challenges resulted in a tailored automated feeding solution that not only met but exceeded the client's expectations, demonstrating Bellco's commitment to delivering quality and efficiency in automated feeding technology.