| Industry: Consumer Products | |

| Rate: 60 parts per minute per system | |

| Hopper Capacity: 60 minute unattended run time | |

About The Project

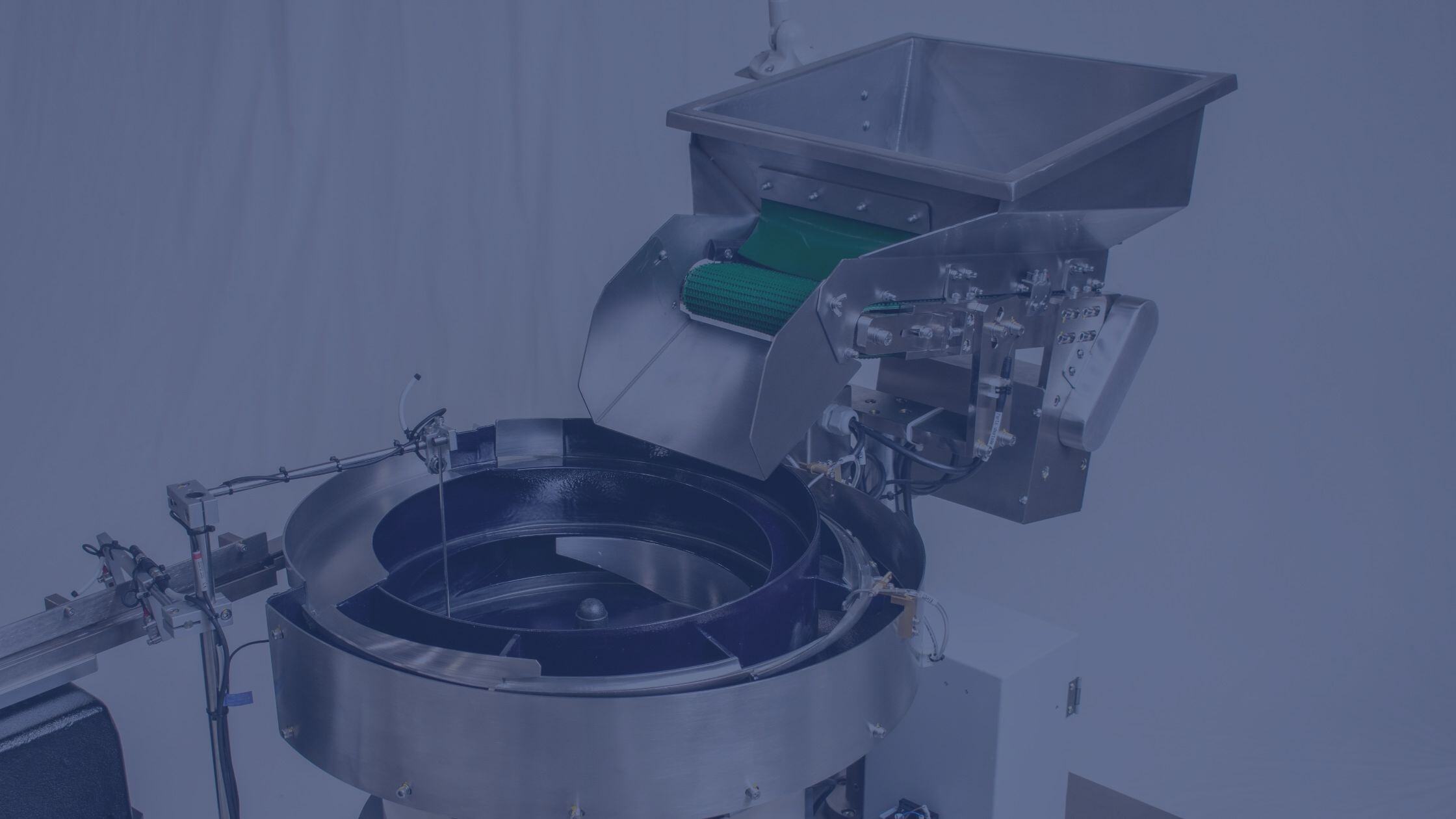

Bellco designed and manufactured three custom vibratory feeder bowls and bulk parts hopper to feed an automated assembly machine that produces insect repellant products. The three products were different sizes and geometries and all needed to be fed at the same rate. The three products included child proof caps, inspect repellant container, and fabric wick.

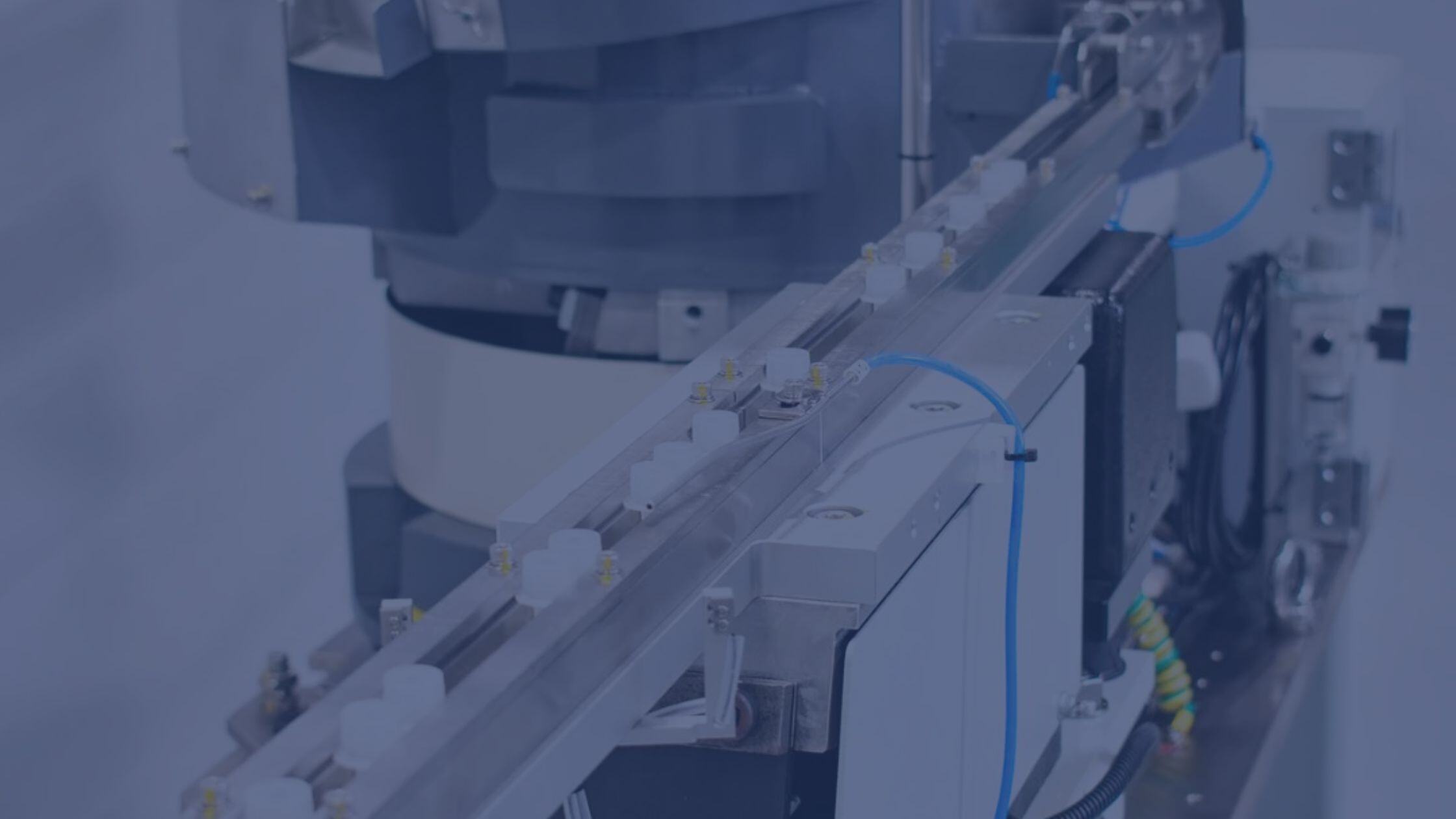

Each vibratory bowl feeder system included:

- Custom welded and painted steel legs

- Bulk parts hoppers

- Linear feeding tracks

- Custom parts escapements

The Results

This was a fun project for our team. We were able to work with the engineering team at the OEM and design custom parts escapements that would feed their pick-and-place applications in their automated machine.

Our team was also able to design all three systems to operate at the same rate which helped the machines overall efficiency.

Our customer was able to enjoy our quick turn-around and was able to integrate this system into their automated machine within 12 weeks of placing the order with Bellco.